BLOG

Top 10 Molding Services: Choosing the Right Provider for Your Project

When embarking on a project that requires precision and attention to detail, selecting the right provider for molding services is vital to ensure the success of your endeavor. Molding services encompass a wide range of processes, from injection molding to blow molding, and choosing the right provider can significantly impact the quality, efficiency, and cost-effectiveness of your production. With numerous companies offering these specialized services, it's essential to understand the key factors that differentiate them and to identify the best fit for your unique project requirements.

In this guide, we present the top 10 molding services available in the industry, helping you navigate the complex landscape of providers. Each of these companies brings valuable expertise and specialized capabilities to the table, catering to various industries and project scopes. By analyzing their offerings, technologies, and standout attributes, you will be better equipped to make an informed decision that aligns with your project's goals, timelines, and budget constraints. Understanding the nuances of molding services will empower you to partner with a provider that not only meets your expectations but also adds value to your overall project.

Overview of Molding Services and Their Importance in Manufacturing

Molding services play a pivotal role in the manufacturing sector, offering essential solutions for producing high-quality components across various industries. These services encompass a range of processes, including injection molding, blow molding, and rotational molding, each tailored to meet specific production needs. The precision and efficiency of these techniques allow manufacturers to create complex shapes and designs that would be difficult or impossible to achieve through traditional machining methods. This not only enhances product quality but also reduces material waste and production time.

Choosing the right molding service provider is crucial for the success of any manufacturing project. Factors such as the provider's experience, technological capabilities, and commitment to quality control can significantly impact the outcome. A reliable partner will not only understand the technical requirements of the project but also offer insights into optimizing the design for manufacturability. This collaboration can ultimately lead to innovative solutions and ensure that products meet both functional requirements and market demands.

Top 10 Molding Services: Choosing the Right Provider for Your Project

| Service Type | Importance | Material Options | Lead Time | Cost Range |

|---|---|---|---|---|

| Injection Molding | High precision and efficiency | Plastics, Elastomers | 2-4 weeks | $5,000 - $100,000 |

| Blow Molding | Ideal for hollow parts | Polyethylene, PVC | 3-6 weeks | $10,000 - $200,000 |

| Thermoforming | Cost-effective for low volume | PVC, PET, PS | 2-5 weeks | $1,000 - $50,000 |

| Compression Molding | Excellent for large parts | Rubber, Thermosets | 3-8 weeks | $2,000 - $75,000 |

| Rotational Molding | Great for complex shapes | Polyethylene, Nylon | 4-8 weeks | $5,000 - $100,000 |

| 2-Shot Molding | Combines two materials | Various plastics | 3-8 weeks | $20,000 - $500,000 |

| Insert Molding | Integrates metal and plastic | Plastics, Metals | 4-6 weeks | $10,000 - $250,000 |

| Die Casting | High-speed production of metal parts | Aluminum, Zinc | 2-4 weeks | $15,000 - $300,000 |

| Plastic Extrusion | Continuous shapes and profiles | PVC, ABS, Polycarbonate | 2-6 weeks | $3,000 - $80,000 |

| 3D Printing | Prototype development and low runs | PLA, ABS, Resin | 1-4 weeks | $500 - $20,000 |

Key Factors to Consider When Choosing a Molding Service Provider

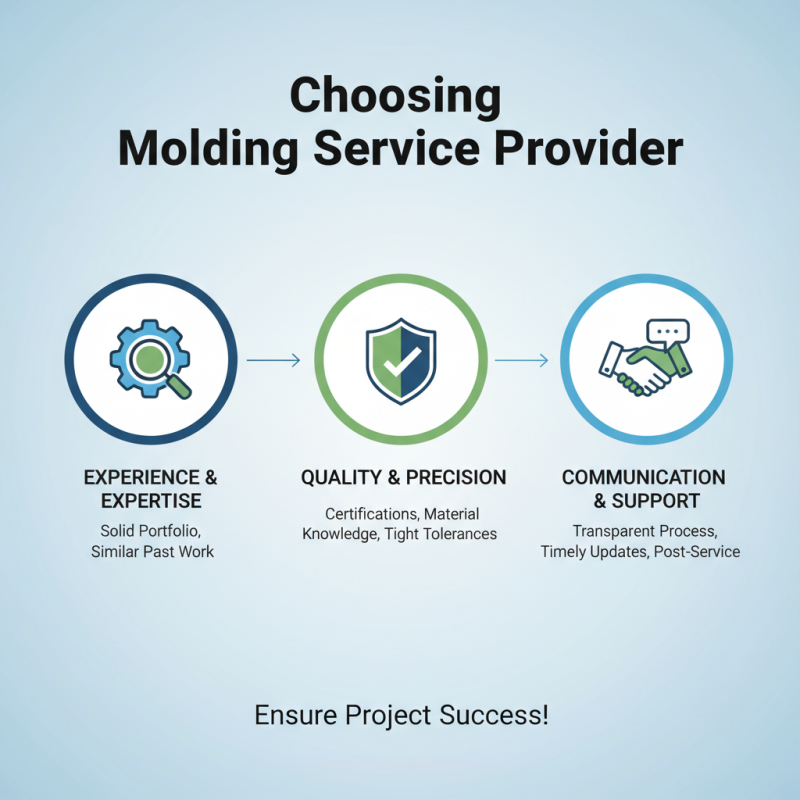

When selecting a molding service provider, several key factors should be considered to ensure the success of your project. First, evaluate the provider's experience and expertise in the industry. A well-established company with a solid portfolio can give you confidence in their ability to meet your specific needs. Look for examples of past work similar to your project, as this can demonstrate their capability and creativity in tackling molding challenges.

Additionally, it is essential to assess the technology and materials used by the provider. Cutting-edge technology not only enhances the quality of the molding process but also ensures efficiency and consistency in production. Furthermore, inquire about the sourcing of materials. Providers that use high-quality, sustainable materials can contribute significantly to the longevity and aesthetic appeal of your final product. Lastly, consider their customer support and communication style, as a provider that values collaboration can help navigate any challenges that may arise during the project.

Types of Molding Processes and Their Applications in Various Industries

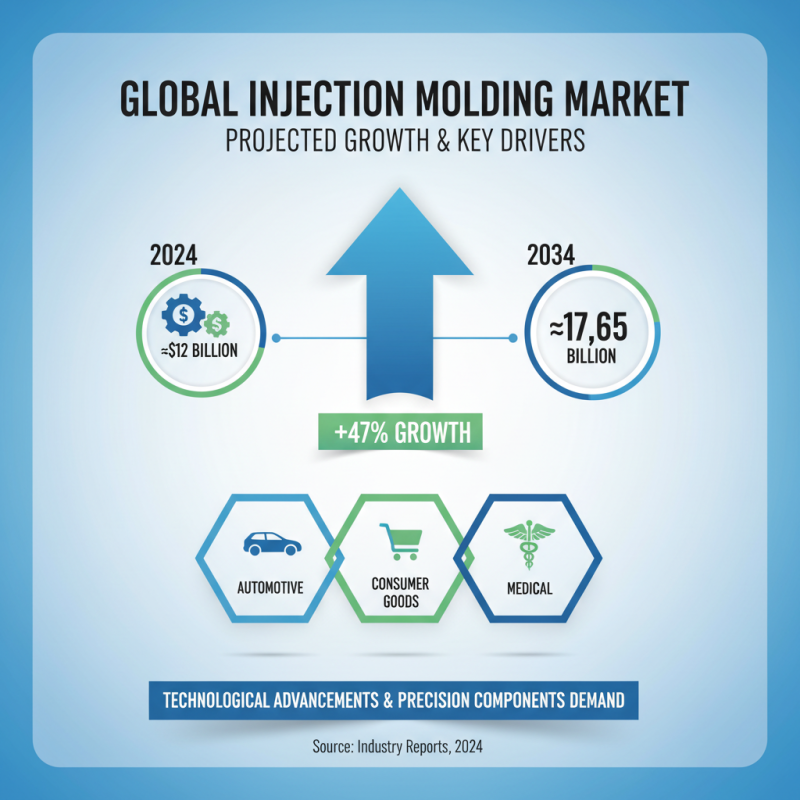

The molding industry encompasses various processes tailored to the specific requirements of different sectors. The injection molding market, a dominant player, is anticipated to expand significantly, with projections estimating a global size of approximately $17.65 billion by 2034. This growth is driven by advances in technology and the increasing demand for precision-engineered plastic components across automotive, consumer goods, and medical industries.

Another noteworthy process is rotational molding, particularly known for its cost-effectiveness in producing large plastic parts. The market for rotational molding materials is expected to grow at a CAGR of 5.7%, with powder materials currently leading the market share. This method is widely utilized in creating tanks, containers, and complex shapes due to its versatility and ability to ensure uniform wall thickness.

Additionally, the vacuum casting market is also seeing considerable growth, reflecting the rising demand for prototypes and smaller production runs. With trends indicating a robust appetite for materials such as polyurethane resin and silicone, the vacuum casting segment is poised to cater to various industries, including electronics and toys. As these molding processes evolve, they continue to transform manufacturing capabilities across multiple sectors.

Evaluating the Capabilities and Experience of Potential Molding Providers

When selecting the right molding service provider for your project, evaluating their capabilities and experience is crucial. Experienced healthcare providers, for instance, have demonstrated their ability to conduct complex assessments, as seen in the recent study assessing ear molding therapy outcomes. This study compared results from seasoned practitioners against advanced technology, highlighting the importance of both human expertise and innovative tools in producing effective outcomes.

Tips for evaluating potential molding providers include reviewing their past projects and client testimonials. A reliable provider should showcase a diverse portfolio that demonstrates their capability to handle various molding techniques and materials. It's also beneficial to inquire about their familiarity with the latest technologies and methodologies, which can enhance the quality of the final product.

Additionally, consider the provider’s experience in your specific industry. Different sectors may require unique approaches and standards, making it essential to find a provider who understands your specific needs. Engaging in direct conversations with potential providers can offer valuable insights into their problem-solving skills and customer service approach, ensuring a smoother collaboration for your project.

Cost Considerations and Budgeting for Molding Projects

When budgeting for molding projects, it is essential to understand the various cost factors involved to make informed decisions. According to a recent industry report from the Market Research Future (MRFR), the global molding market is projected to reach USD 300 billion by 2026, indicating a growing demand for quality services. The costs associated with molding can vary significantly based on the materials used, the complexity of the design, and the production volume. For instance, injection molding often requires substantial upfront investments in molds, which can range from $1,000 to over $100,000 depending on complexity and durability.

Moreover, ongoing operational costs play a crucial role in overall budgeting. The Plastics Industry Association (PIA) highlights that energy consumption accounts for approximately 30% of the operational expenses in molding processes. Therefore, it is prudent to choose providers who utilize energy-efficient technologies to keep long-term expenses in check. As you evaluate your options, consider these financial aspects and seek partners that can offer transparency regarding their pricing structures and cost-saving solutions, ultimately helping you stay within budget while achieving high-quality results.

Related Posts

-

Understanding the Role of Plastic Injection Companies in Sustainable Manufacturing Practices

-

How to Optimize the Injection Moulding Process for Better Efficiency and Quality

-

Exploring the Future of Injection Tooling Innovations and Trends

-

How to Choose the Right Molding Plastic for Your Next Project

-

Everything You Need to Know About Plastic Trim: Uses, Benefits, and Maintenance Tips

-

How Custom Injection Molded Parts Revolutionize Modern Manufacturing Techniques

Our Promise to You

All products and services provided by Innovative Plastic Molders, Inc. will meet or exceed our customer's perceived requirements and expectations. We will listen and respond to what our customers are telling us in a timely and forthright manner.

ISO 9001:2015 CERTIFIED

© Copyright 2009 – Innovative Plastic Molders, Inc.

Website by Central 8 Marketing

Contact IPM

10451 Dog Leg Road Ste 200

Vandalia, OH 45377

Phone: 937.898.3775

Fax: 937.535.0640

Email: sale@endtheplastic.com