BLOG

Top 10 Benefits of Injection Molding for Manufacturing Efficiency

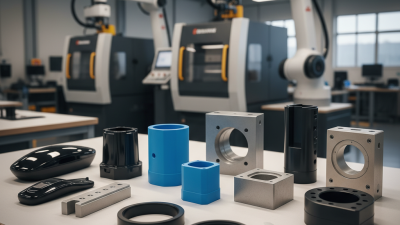

Injection molding is a transformative manufacturing process that has revolutionized the production line, enabling businesses to enhance their efficiency and output. This advanced technique involves injecting molten material into a mold to create precise and complex components, making it a popular choice across various industries, from automotive to consumer goods. The benefits of injection molding extend beyond mere production capabilities; they significantly impact the overall efficiency and cost-effectiveness of manufacturing operations.

As market demands continue to evolve, manufacturers are under increasing pressure to adopt methods that promote not only speed but also sustainability and precision in their production processes. The advantages of injection molding align perfectly with these needs, offering reduced waste, improved material utilization, and faster turnaround times. In this article, we will explore the top 10 benefits of injection molding, highlighting how this method can enhance manufacturing efficiency and position companies for competitive success in today's fast-paced marketplace.

Overview of Injection Molding Process and Its Significance

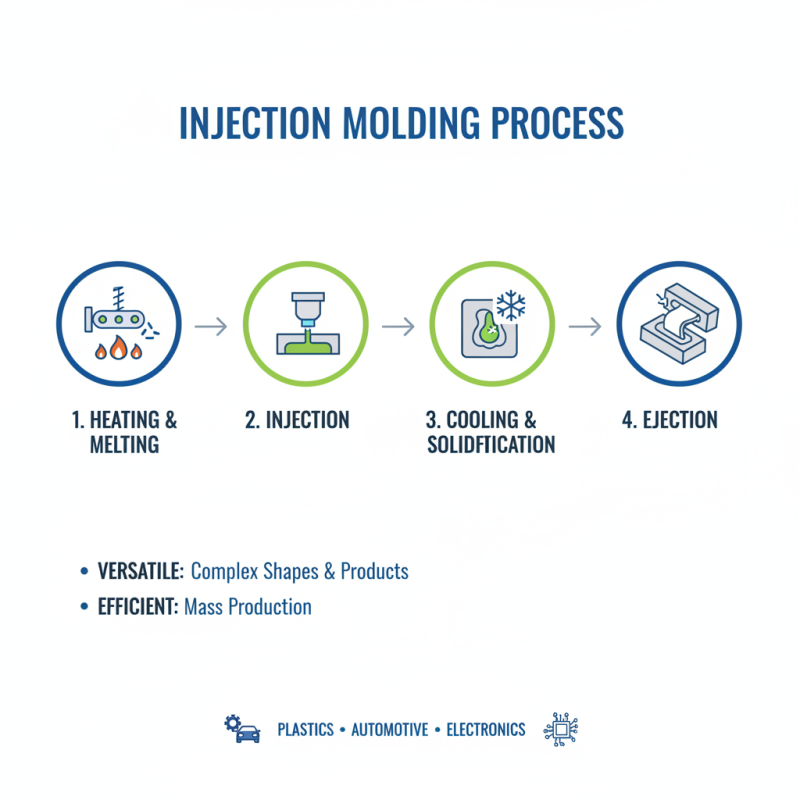

Injection molding is a manufacturing process that involves injecting molten material into a mold to create a wide variety of products. This method is particularly significant in the production of plastic components, which are omnipresent in various industries, including automotive, consumer goods, and electronics. The process begins with the heating of plastic pellets until they reach a molten state, followed by the injection of this liquid material into a precisely designed mold. Once the material cools and solidifies, the mold is opened, and the finished part is ejected.

The significance of injection molding lies in its ability to produce high volumes of parts with exceptional accuracy and repeatability. This efficiency not only streamlines the manufacturing process but also reduces production costs over time. Moreover, injection molding permits the use of complex designs and intricate geometries, allowing manufacturers to innovate and enhance product features. Furthermore, the ability to use a range of materials, including various plastics, thermoplastics, and composites, makes injection molding a versatile option for industry-specific applications, catering to the diverse needs of manufacturers and consumers alike.

Reduction of Material Waste Through Efficient Design and Use

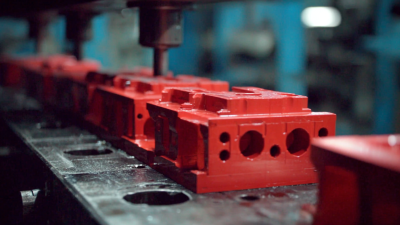

Injection molding has become a cornerstone of modern manufacturing, particularly due to its capacity to minimize material waste through innovative design and application. At the heart of this efficiency lies the meticulous engineering of molds, which allows manufacturers to produce complex parts with precision. By optimizing the geometry and design features, designers are able to maximize the use of raw materials, ensuring that only the necessary amount is utilized for each component. This leads to significant reductions in excess waste, which not only conserves resources but also lowers production costs.

Moreover, the ability to recycle and reuse material in the injection molding process further enhances its sustainability. Many manufacturers incorporate post-consumer recycled plastics into their production lines, which aligns with contemporary eco-friendly practices. The closed-loop system of injecting and recapturing material means that any surplus can be processed and reintroduced into future production cycles. This recycling capability, combined with careful design practices, positions injection molding as a highly efficient choice for manufacturers aiming to reduce their environmental footprint while simultaneously improving operational efficiency.

Top 10 Benefits of Injection Molding for Manufacturing Efficiency

| Benefit | Description | Impact on Material Waste |

|---|---|---|

| Design Flexibility | Ability to create complex shapes while minimizing materials. | Reduces excess materials used. |

| Material Optimization | Utilizes advanced materials tailored for specific applications. | Minimizes scrap and waste. |

| High Production Speed | Fast cycle times increase production volume. | Balances production efficiency with waste reduction. |

| Consistency and Repeatability | Ensures uniformity in each part produced. | Reduces rejects and wasted materials. |

| Automated Processes | Integration of robotics and automation in production. | Minimizes human error, reducing waste. |

| Tooling Efficiency | Precision tooling leads to lower material usage. | Decreases material waste during production. |

| Product Life Cycle | Longer-lasting products reduce the need for replacements. | Less waste generated from discarded items. |

| Reduced Post-Processing | Less finishing work needed compared to other methods. | Conserves materials and labor. |

| Recycling Capabilities | Many injection molded materials can be recycled. | Promotes sustainability and waste reduction. |

| Cost-Effectiveness | Lower overall costs due to reduced waste and faster production. | Beneficial impact on resource management. |

Enhanced Production Speed and Cycle Time Efficiency

Injection molding is a manufacturing process that significantly enhances production speed, contributing to overall cycle time efficiency. The technique allows for high-volume production of parts with intricate designs and consistent precision. One of the primary advantages is the ability to produce complex geometries quickly; molds can be reused extensively, reducing the time and resources spent on tooling. This repeatability is crucial for maintaining quality while ramping up production, ensuring that manufacturers can meet market demands without sacrificing standards.

Moreover, the rapid cycle times inherent in injection molding enable manufacturers to maximize their output. Each cycle can range from a few seconds to a couple of minutes, depending on the part size and complexity, allowing for swift turnaround times on large orders. This efficiency reduces lead times significantly, enabling businesses to respond quickly to changing customer needs. Additionally, the automation possibilities in the injection molding process can further enhance production speed, as machines can operate continuously with minimal manual intervention, allowing manufacturers to focus resources on other critical areas of production.

Top 10 Benefits of Injection Molding for Manufacturing Efficiency

Versatility in Material Selection for Diverse Applications

Injection molding has become a cornerstone of modern manufacturing due to its unparalleled versatility in material selection. According to a report by the American Society for Testing and Materials (ASTM), more than 30,000 unique types of plastics are available for injection molding, including thermoplastics, thermosetting plastics, and elastomers. This wide variety allows manufacturers to choose materials that best meet the specific requirements of their projects, whether they demand extreme durability, flexibility, or high-temperature resistance. The ability to pick from such a diverse material pool significantly enhances the adaptability of manufacturing processes across various industries, including automotive, consumer goods, and medical devices.

Moreover, a study published in the Journal of Applied Polymer Science indicates that the use of innovative materials, such as bio-based and recycled plastics, in injection molding is on the rise. This shift reflects growing consumer demand for sustainable products, enabling manufacturers to reduce their ecological footprint while maintaining high production efficiency. As the industry increasingly adopts more advanced materials, it can also improve performance attributes like weight reduction and thermal management, essential for applications in sectors like aerospace and electronics. This adaptability not only drives production efficiency but also positions companies to respond swiftly to changing market demands and technological advancements.

Cost-Effectiveness and Long-Term Savings in Manufacturing

Injection molding stands out as a cornerstone of modern manufacturing due to its ability to provide significant cost-effectiveness and long-term savings. This method utilizes advanced technology to produce high volumes of parts with remarkable precision and consistency, drastically reducing production costs per unit. By utilizing thermoplastics and other materials efficiently, manufacturers can achieve high production rates while minimizing waste. The cycle time associated with injection molding is considerably shorter compared to traditional manufacturing methods, enabling businesses to meet market demands swiftly and remain competitive.

Tip: To maximize the cost-effectiveness of injection molding, consider investing in design optimization. Collaborate with designers during the early stages of product development to ensure that the components are suitable for injection molding. This proactive approach can significantly reduce material usage and cut down on unnecessary rework, leading to additional savings.

Long-term savings are also realized through durability and reduced maintenance costs. Injected molded parts tend to have a longer lifespan, which means fewer replacements and repairs over time. Furthermore, the consistency in quality leads to decreased defects, minimizing waste and enhancing overall production efficiency. Implementing energy-efficient practices in the injection molding process can further drive down operational costs, contributing to a healthier bottom line for manufacturers.

Tip: Regularly review and update your production processes to incorporate technological advancements in injection molding. Staying informed about the latest machinery and materials can lead to opportunities for further savings and efficiency improvements in your manufacturing operations.

Related Posts

-

Exploring the Future of Injection Tooling Innovations and Trends

-

The Future of Manufacturing How Injection Molding Companies are Revolutionizing Production Processes

-

10 Best Injection Molded Parts for Your Manufacturing Needs

-

Understanding the Plastic Injection Moulding Process for Efficient Manufacturing

-

Top 10 Best Molded Parts for Your Manufacturing Needs in 2023

-

2025 How to Choose the Best Custom Molding for Your Project

Our Promise to You

All products and services provided by Innovative Plastic Molders, Inc. will meet or exceed our customer's perceived requirements and expectations. We will listen and respond to what our customers are telling us in a timely and forthright manner.

ISO 9001:2015 CERTIFIED

© Copyright 2009 – Innovative Plastic Molders, Inc.

Website by Central 8 Marketing

Contact IPM

10451 Dog Leg Road Ste 200

Vandalia, OH 45377

Phone: 937.898.3775

Fax: 937.535.0640

Email: sale@endtheplastic.com