BLOG

Top 10 Tips to Choose the Right Injection Machine for Your Manufacturing Needs

When it comes to selecting the perfect injection machine for your manufacturing needs, understanding the various factors that influence this choice is crucial. Renowned industry expert, Dr. Emily Carter, a leading authority in injection molding technology, emphasizes the importance of this decision, stating, "Choosing the right injection machine is not just about the initial cost; it’s about aligning the machine’s capabilities with your production goals."

Injection machines are at the heart of numerous manufacturing processes, making the selection process pivotal to achieving both efficiency and product quality. From determining the right size and type of machine to considering factors such as material compatibility and production volume, each decision plays a significant role in streamlining operations. As businesses strive for optimization, the right injection machine can lead to enhanced productivity, reduced waste, and improved overall outcomes.

In this article, we will explore the top ten tips for choosing the appropriate injection machine tailored to your specific manufacturing needs, ensuring that your investment is both strategic and sustainable in today's competitive market. By keeping in mind the insights from experts like Dr. Carter, manufacturers can make informed decisions that lead to long-term success.

Understanding Your Manufacturing Requirements for Injection Machines

Understanding your manufacturing requirements for injection machines is crucial in optimizing productivity and ensuring quality output. The first step in this evaluation process involves identifying the specific materials used in your production, as different polymers have varying viscosity and melting points that could dictate the type of injection machine needed. According to a recent report by MarketsandMarkets, the global injection molding machine market is projected to grow from USD 19.92 billion in 2021 to USD 32.07 billion by 2026. This growth highlights the increasing importance of selecting the right equipment tailored to specific manufacturing needs.

Moreover, it is essential to analyze the production volume and cycle times that your processes demand. Machines are available in various clamping force capacities, and understanding your desired output can help in selecting machinery that can efficiently handle production runs without frequent downtime. Data from Gardner Business Media suggests that companies can experience a substantial increase in throughput—up to 30% or more—by choosing machines that align closely with their product specifications and operational goals. By gaining a clear understanding of these manufacturing requirements, businesses can make informed decisions that will enhance overall production efficiency and competitiveness in the market.

Top 10 Tips to Choose the Right Injection Machine for Your Manufacturing Needs

This bar chart demonstrates the importance of various factors when selecting an injection machine, based on manufacturing requirements.

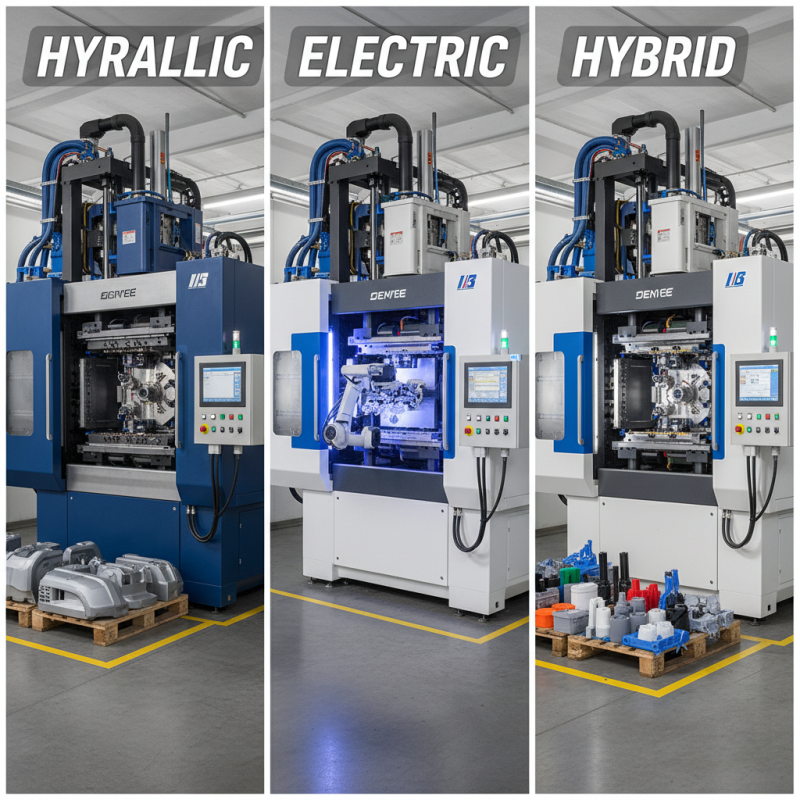

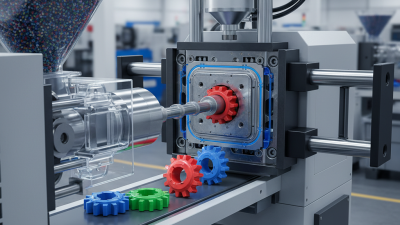

Evaluating Different Types of Injection Machines Available

When selecting an injection machine for your manufacturing needs, it’s crucial to evaluate the different types available to ensure you choose one that aligns with your production goals. Injection molding machines can vary significantly in their design and functionality, catering to diverse applications. The fundamental categories include hydraulic, electric, and hybrid models. Hydraulic machines are known for their high clamping force and are suitable for large parts, while electric machines offer precision and energy efficiency, making them ideal for intricate designs. Hybrid machines combine elements of both and can be a tailored solution for specific manufacturing challenges.

It is essential to consider your production volume and the types of materials you will use. For smaller production runs, an electric machine may provide the best efficiency. In contrast, hydraulic machines may excel in high-volume settings, where speed and clamping force are paramount. Additionally, understanding the potential for automation can further enhance productivity. Implementing automation can reduce cycle times and improve overall efficiency. Assessing these needs will help ensure your investment meets your operational demands and prepares you for future growth.

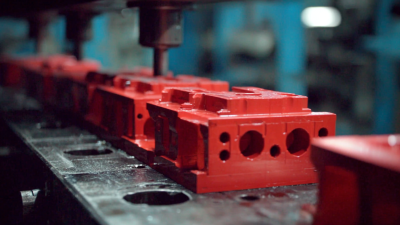

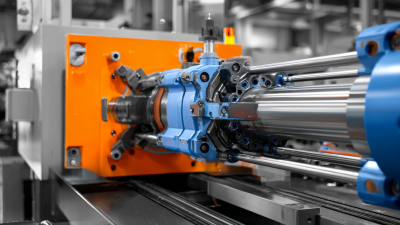

Key Specifications to Consider When Choosing an Injection Machine

When selecting the right injection machine for your manufacturing needs, key specifications play a pivotal role in ensuring efficiency and productivity. One of the most critical factors to consider is clamping force, which ranges typically from 20 to 5,000 tons depending on the application. Data from the Plastics Industry Association indicates that improper clamping force can lead to defects in the final product, costing manufacturers up to 20% of their production efficiency. It is essential to evaluate the clamping force required for the specific materials being used, as well as the complexity of the parts being produced.

Another important specification is injection speed and volume, as these directly impact cycle time and overall output. Industry research suggests that machines with high injection speeds, ranging from 60 to 120 cm³/s, significantly reduce cycle times, enhancing throughput. Additionally, shot size should align with the parts to be produced; for example, a machine should have an injection volume that can accommodate the largest shot size required, ensuring it can handle demanding production runs. Furthermore, technologies such as servo-driven systems can provide optimized energy consumption and enhanced precision, which is increasingly a requirement in modern manufacturing environments. Therefore, careful consideration of these specifications is vital for manufacturers looking to optimize their processes and meet market demands.

Assessing the Cost-Effectiveness of Injection Machines

When assessing the cost-effectiveness of injection machines, it’s crucial to analyze initial investment versus long-term operational costs. The initial purchase price of the machine is often just the beginning; manufacturers should also account for maintenance, repairs, and the availability of replacement parts. A machine that appears cheaper upfront may incur higher costs over time due to inefficient energy use or frequent breakdowns. Therefore, a thorough evaluation of the machine's design and reliability is essential to ensure it aligns with budget expectations and operational needs.

Additionally, production efficiency plays a significant role in cost-effectiveness. Factors such as cycle time, throughput, and the quality of finished products can greatly influence overall expenses. A high-quality injection machine may have a higher initial cost, but if it significantly reduces cycle times and minimizes waste, the return on investment can justify the expense. Manufacturers should also consider the adaptability of the machine to varying production runs; machines that can accommodate different mold sizes or materials can lead to greater flexibility and cost savings in the long term. Thus, careful evaluation of both initial and ongoing costs is key to making an informed decision that best meets manufacturing needs.

Researching Supplier Reputation and Support Services

When selecting an injection machine for your manufacturing needs, it's crucial to prioritize supplier reputation and support services. A well-regarded supplier often reflects reliability and quality in their machinery. Researching potential suppliers involves examining their history, client testimonials, and industry standing. Companies with a long track record of satisfied customers are usually equipped to provide innovative and effective solutions tailored to your specific production requirements.

Moreover, support services offered by suppliers play a significant role in your decision-making process. Assess their customer service capabilities, including technical support, maintenance services, and response times. A supplier that provides robust after-sales support can help mitigate operational downtime and enhance productivity. Engaging with suppliers that offer comprehensive training for your staff ensures seamless integration of the new equipment, maximizing its efficiency from the outset. Prioritizing these factors can lead to a more informed purchase that aligns perfectly with your manufacturing goals.

Related Posts

-

10 Best Injection Molded Parts for Your Manufacturing Needs

-

Understanding the Plastic Injection Moulding Process for Efficient Manufacturing

-

2025 How to Choose the Best Custom Molding for Your Project

-

How to Optimize the Injection Moulding Process for Better Efficiency and Quality

-

10 Essential Tips to Optimize Your Plastic Injection Moulding Process Efficiency

-

The Future of Manufacturing How Injection Molding Companies are Revolutionizing Production Processes

Our Promise to You

All products and services provided by Innovative Plastic Molders, Inc. will meet or exceed our customer's perceived requirements and expectations. We will listen and respond to what our customers are telling us in a timely and forthright manner.

ISO 9001:2015 CERTIFIED

© Copyright 2009 – Innovative Plastic Molders, Inc.

Website by Central 8 Marketing

Contact IPM

10451 Dog Leg Road Ste 200

Vandalia, OH 45377

Phone: 937.898.3775

Fax: 937.535.0640

Email: sale@endtheplastic.com