BLOG

Why is a Plastic Molding Machine Essential for Modern Manufacturing?

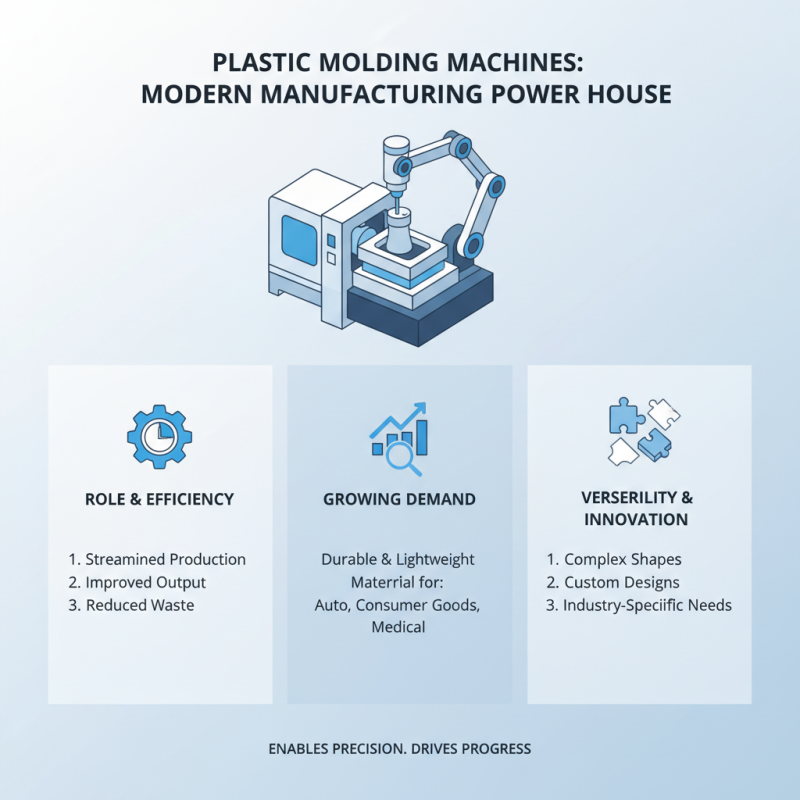

In today's manufacturing landscape, the significance of a plastic molding machine cannot be overstated. According to a report from Grand View Research, the global plastic molding market is expected to reach $665 billion by 2025. This growth is driven by the demand for lightweight and durable materials across various industries. However, not all plastic molding technologies yield the same results, highlighting the need for innovation and efficiency.

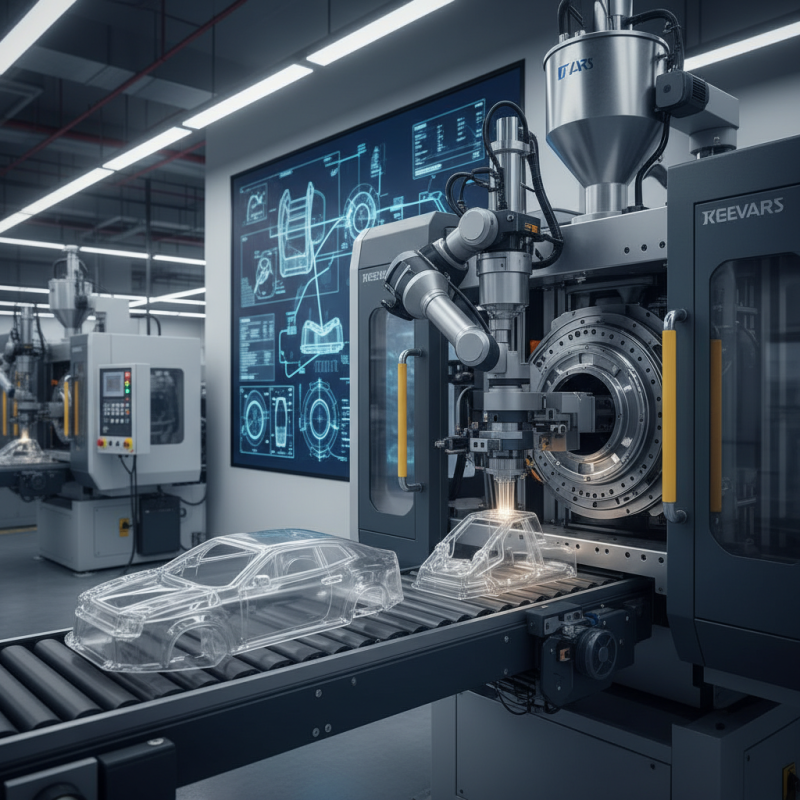

Dr. Emily Chen, a leading expert in plastic engineering, emphasizes, "The plastic molding machine is a cornerstone of modern production." This statement reflects the reality that effective manufacturing relies heavily on these machines. They enable precision, reduce material waste, and optimize production time. Yet, there are challenges. Many businesses face outdated machinery that limits their output quality and efficiency.

As the industry evolves, integrating advanced plastic molding machines is critical. Companies that fail to adapt risk falling behind competitors who leverage cutting-edge technology. To maintain relevance, manufacturers must assess their equipment and seek improvements. The future of manufacturing hinges on our ability to optimize plastic molding processes and meet the ever-increasing demands for quality and innovation.

The Role of Plastic Molding Machines in Modern Production Processes

Plastic molding machines play a vital role in modern manufacturing. They streamline the production of various plastic products, improving efficiency. With the growing demand for durable and lightweight materials, these machines are indispensable. They enable manufacturers to create complex shapes that meet specific needs. This versatility helps industries like automotive, consumer goods, and medical devices.

When considering a plastic molding machine, note the importance of proper maintenance. Regular checks can enhance performance and lifespan. A simple observation can prevent major breakdowns. Keep the machine clean and lubricated. Track historical performance data and adjust operations accordingly.

Investing in a plastic molding machine represents a significant commitment. Initial costs may deter some, but the long-term benefits are clear. Operators must be trained effectively, ensuring they understand the machine's capabilities. Mistakes can lead to waste and inefficiency. Taking deliberate time for training can pay off immensely.

Types of Plastic Molding Techniques Utilized in Manufacturing

Plastic molding techniques play a vital role in modern manufacturing. They allow for mass production of various goods. Each technique has unique advantages that cater to different needs.

Injection molding is the most common method. It involves injecting molten plastic into a mold. This process creates precise shapes and is ideal for complex designs. However, it may lead to waste if the mold is not designed properly. Designers should work closely with engineers to optimize the process.

Blow molding is another technique. It forms hollow objects by inflating hot plastic. This method is popular for producing bottles. Quality control is crucial here to avoid defects. Regular maintenance of machinery can prevent lots of wasted resources.

Tips: Always double-check mold designs before production. A well-designed mold reduces waste significantly. Don’t overlook the importance of choosing the right material for your product. The wrong choice can lead to costly errors and redesigns.

Why is a Plastic Molding Machine Essential for Modern Manufacturing? - Types of Plastic Molding Techniques Utilized in Manufacturing

| Molding Technique | Description | Applications | Advantages | Materials Used |

|---|---|---|---|---|

| Injection Molding | Process of injecting molten plastic into a mold to create parts. | Automotive parts, consumer products, medical devices | High efficiency, complex shapes, fast production rates | Polypropylene, ABS, Polycarbonate |

| Blow Molding | Creating hollow plastic parts by blowing air into a heated plastic tube. | Bottles, containers | Low cost, lightweight, suitable for large production runs | Polyethylene, PVC |

| Rotational Molding | A process that involves rotating a mold around an axis to evenly coat the interior with plastic. | Kayaks, large storage tanks, toys | Versatility, larger size options, no pressure required | Polyethylene, Nylon |

| Thermoforming | Heating plastic sheets until pliable, then forming over a mold. | Packaging, automotive interiors | Cost-effective for short runs, rapid prototyping | PVC, PS, ABS |

| Compression Molding | A method where plastic is placed in a heated mold and compressed to form. | Electrical insulators, rubber products | Low tooling cost and great for short production runs | Phenolic, Silicone |

Benefits of Using Plastic Molding Machines for Efficiency and Cost-Effectiveness

Plastic molding machines play a crucial role in modern manufacturing. They offer efficiency and cost-effectiveness, crucial for industries today. These machines can produce complex shapes quickly and consistently. This precision minimizes material waste, allowing companies to save on raw materials.

Using plastic molding reduces labor costs as well. Automated processes streamline production. Fewer workers are needed for assembly lines. However, initial investments can be high. Companies must carefully consider their budgets before purchasing.

Despite their benefits, challenges may arise. Machine maintenance is essential for optimal performance. Neglecting this can lead to costly downtime. Managers must regularly check equipment. This reflection helps in making continuous improvements to their production processes.

Impact of Plastic Molding Machines on Modern Manufacturing

Impact of Plastic Molding Technology on Product Design and Innovation

Plastic molding technology revolutionizes product design and innovation. It allows designers to explore complex shapes and structures that were previously impossible. With 3D modeling software, designers visualize products before they are created. This pre-production phase saves both time and resources. Mistakes can be identified early, reducing waste during manufacturing.

The versatility offered by plastic molding machines is unmatched. They enable mass production of intricate designs. This capability helps bring creative ideas to life quickly. However, reliance on this technology can lead to a lack of originality. Some designers may lean too heavily on standard molds. Innovation may suffer as a result, stifling unique concepts.

Additionally, the speed of production can create pressure to prioritize quantity over quality. Manufacturers might rush products to market, risking defects. Balancing efficiency with craftsmanship is key. It’s vital for designers to continually seek inspiration from various sources. Exploring new materials and techniques can pave the way for true innovation in the world of plastic molding.

Future Trends in Plastic Molding Machinery and Their Manufacturing Implications

The landscape of plastic molding machinery is evolving rapidly. New technologies emerge, enhancing production efficiency. Automation plays a key role. Machines now use advanced sensors for real-time adjustments. This allows manufacturers to optimize processes dynamically. It reduces material waste significantly, something that many companies struggle with.

Sustainability is another growing trend. Biodegradable plastics are gaining traction. Manufacturers face challenges with these new materials. Equipment must be adaptable and versatile. Some machines struggle with processing these types of plastics efficiently. This poses questions about future investments. Can machines keep up with changing material demands?

The rise of smart manufacturing is shaping the future. Integrating IoT into machinery helps with predictive maintenance. However, this transition isn't seamless. Many facilities grapple with outdated machines. Upgrades require substantial resources. Businesses must weigh costs against potential benefits. The journey towards modernization is complex but necessary.

Related Posts

-

Top 10 Tips to Choose the Right Injection Machine for Your Manufacturing Needs

-

Top 10 Benefits of Custom Plastic Injection Molding for Your Business

-

How to Choose the Best Plastic Injection Molding Company for Your Needs

-

Top Benefits of Custom Plastic Injection Molding for Your Business Needs

-

2025 How to Choose the Best Custom Molding for Your Project

-

Top Applications of Plastic Injection Molding in Various Industries?

Our Promise to You

All products and services provided by Innovative Plastic Molders, Inc. will meet or exceed our customer's perceived requirements and expectations. We will listen and respond to what our customers are telling us in a timely and forthright manner.

ISO 9001:2015 CERTIFIED

© Copyright 2009 – Innovative Plastic Molders, Inc.

Website by Central 8 Marketing

Contact IPM

10451 Dog Leg Road Ste 200

Vandalia, OH 45377

Phone: 937.898.3775

Fax: 937.535.0640

Email: sale@endtheplastic.com