BLOG

What is the Plastic Injection Moulding Process Explained?

In the world of manufacturing, the plastic injection moulding process is essential. This technique shapes plastic into various forms, widely used in numerous industries. According to Dr. Emily Chen, a leading expert in this field, "The plastic injection moulding process transforms raw materials into intricate designs effortlessly." Her words capture the significance of this process.

This method involves injecting molten plastic into a mould, where it cools and hardens. It’s a fascinating blend of science and creativity. Precision is crucial. Even slight variations can lead to defects. Not every design meets expectations; even seasoned engineers sometimes struggle with complexities.

The plastic injection moulding process can create high-quality products efficiently. However, challenges remain. Material waste occurs, and energy consumption can be high. These aspects demand attention. Continuous improvement and innovation are needed to enhance sustainability. Embracing change in this process is vital for future growth.

Overview of Plastic Injection Moulding Process

Plastic injection moulding is a widely used manufacturing process. It turns raw plastic into complex parts efficiently. The process involves melting plastic pellets, injecting the molten material into a mould, and allowing it to cool. This method offers high precision and repeatability, making it ideal for producing large quantities.

Data shows that the global plastic injection moulding market is projected to reach $344.11 billion by 2027, reflecting its growing importance. However, challenges remain. The energy consumption during production is significant. Industry reports highlight that about 55% of manufacturers are looking for ways to reduce their environmental impact.

Despite its advantages, the process isn’t without flaws. Mould design requires careful consideration. Poorly designed moulds can lead to defects and wasted materials. Each step must be scrutinized to avoid costly mistakes. Continuous improvement and innovation are key to overcoming these challenges. Reducing waste is also becoming a priority in the industry.

Overview of Plastic Injection Moulding Process

Key Components of Injection Moulding Machinery

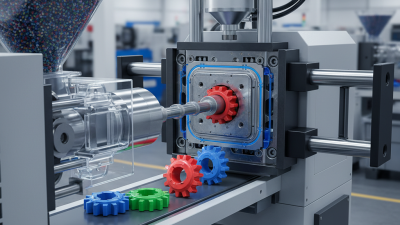

Injection moulding is a key process in manufacturing plastic parts. Understanding the machinery used in this process is essential. The main components include the injection unit, the clamping unit, and the control system.

The injection unit melts raw plastic pellets. A barrel and screw are often found here. The screw rotates, pushing the plastic towards the mold. Temperature control is critical. If the plastic is too hot or too cold, it can lead to defects. This can be frustrating for engineers aiming for perfection.

The clamping unit holds the mold tightly during injection. If the mold isn't clamped properly, material might leak. This creates waste and can compromise the final product. The control system oversees the entire operation. It manages speed, temperature, and pressure. This automation is vital but not flawless. Mistakes can happen. Regular maintenance and calibration are needed to avoid issues. These components work together, but they need constant monitoring to function correctly.

Step-by-Step Procedure of the Injection Moulding Process

The plastic injection moulding process involves several key steps. Raw plastic pellets are heated until molten. This molten material is then injected into a metal mold. The mold cools and hardens, forming the desired shape. The process is widely used, producing about 30% of all plastic items in the market today. Efficiency can lead to large production volumes quickly but requires precision.

Tips: Monitor temperature closely. Variations can lead to defects. Use quality materials to improve durability.

After the mold is filled, it must cool sufficiently. This stage can take several seconds to minutes, depending on the part size. Quick cooling might cause warping, while slow cooling can extend production time. Balancing both is crucial for quality. A poorly cooled part may lead to high rejection rates.

Tips: Experiment with cooling times. Optimize for your specific product.

Once cooled, the mold opens, and the part is ejected. This can be tricky, as residual pressure may cause deformations or even damage. Inspect the parts right after ejection thoroughly. A systematically flawed injection process can accumulate defects, impacting the entire production line efficiency. Regular maintenance of molds is essential to minimize such issues.

Common Materials Used in Plastic Injection Moulding

Plastic injection moulding is a popular manufacturing process. It enables the production of various parts using different materials. Choosing the right material is crucial for achieving the desired product quality and performance.

Common materials used in plastic injection moulding include thermoplastics and thermosets. Thermoplastics like ABS and polycarbonate are known for their flexibility and impact resistance. They can be reshaped multiple times without losing properties.

Thermosetting plastics, such as epoxy and phenolic resin, provide excellent heat resistance. They harden permanently after curing and cannot be remolded. Each type of material has unique characteristics. Consider the application when selecting a material.

Tips: When choosing materials, think about the final environment. Will it face high temperatures or chemicals? These factors can affect material performance. Always prototype with less expensive materials before scaling up. This helps identify potential issues early on.

It's essential to understand that not all materials work well together. Mixing different types can lead to weak points in the final product. Experimentation is key, but failures are part of the process. They can provide valuable insights for future projects.

Applications and Advantages of Plastic Injection Moulding

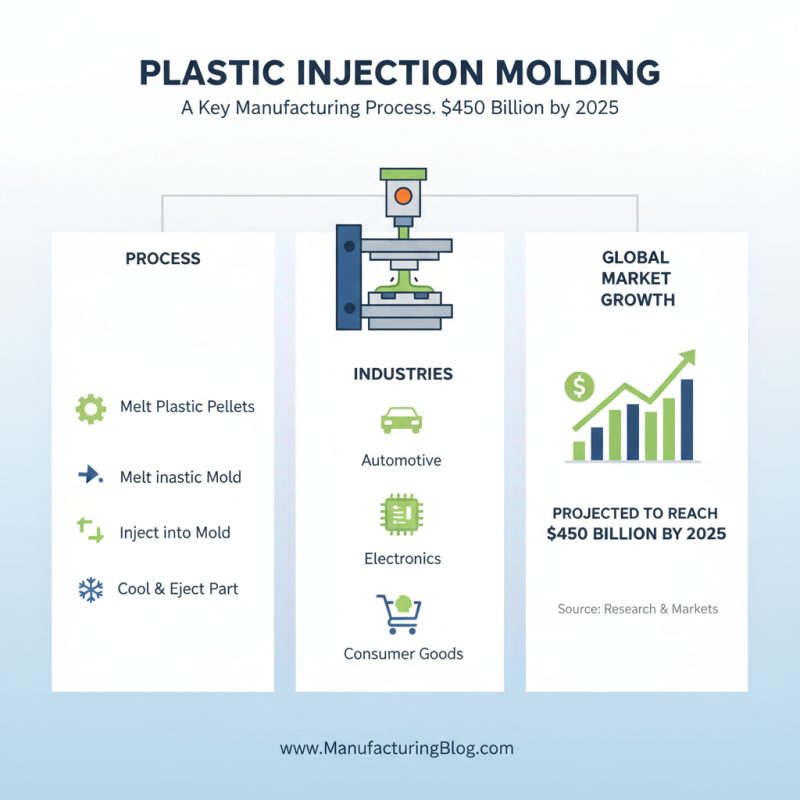

Plastic injection moulding is a prevalent manufacturing process. It is widely used in various industries, including automotive, electronics, and consumer goods. According to a report by Research and Markets, the global plastic injection molding market is projected to reach $450 billion by 2025. This indicates a growing reliance on this technology.

One of the key advantages of this process is efficiency. Injection moulding enables high production rates with minimal waste. Once the mould is created, thousands of parts can be produced quickly. This method also allows for intricate designs that can be produced with precision. However, the initial cost of mould design and manufacturing can be significant. Companies need to weigh this upfront investment against long-term gains.

Applications of plastic injection moulding span many sectors. In the automotive industry, components like dashboards and bumpers are often produced using this technique. In electronics, cases for devices are typically injection molded. However, the industry faces criticism regarding sustainability. Plastic waste poses an environmental challenge. Companies must innovate and consider more eco-friendly materials to mitigate this issue, ensuring that growth doesn’t come at the cost of the planet.

Related Posts

-

Understanding the Plastic Injection Moulding Process for Efficient Manufacturing

-

Understanding the Role of Plastic Injection Companies in Sustainable Manufacturing Practices

-

Exploring the Future of Injection Tooling Innovations and Trends

-

How Custom Injection Molded Parts Revolutionize Modern Manufacturing Techniques

-

Exploring the Future of Injection Molding Companies: Innovations and Trends in Manufacturing

-

10 Essential Tips to Optimize Your Plastic Injection Moulding Process Efficiency

Our Promise to You

All products and services provided by Innovative Plastic Molders, Inc. will meet or exceed our customer's perceived requirements and expectations. We will listen and respond to what our customers are telling us in a timely and forthright manner.

ISO 9001:2015 CERTIFIED

© Copyright 2009 – Innovative Plastic Molders, Inc.

Website by Central 8 Marketing

Contact IPM

10451 Dog Leg Road Ste 200

Vandalia, OH 45377

Phone: 937.898.3775

Fax: 937.535.0640

Email: sale@endtheplastic.com