BLOG

10 Essential Tips for Choosing the Right Plastic Injection Molding Machine

In the competitive landscape of manufacturing, selecting the right plastic injection molding machine is crucial for ensuring efficiency, quality, and profitability. According to the International Association of Plastics Distribution, the global plastic injection molding market is poised to reach $366 billion by 2025, underscoring the significance of this technology in the production process. As companies strive to optimize their operations, understanding the nuances of choosing the appropriate equipment becomes paramount.

Expert in the field, Dr. Emily Turner, a renowned consultant in plastic manufacturing, emphasizes the importance of this decision: "The right plastic injection molding machine can significantly enhance production capabilities and reduce operational costs." With the market evolving rapidly, factors such as machine specifications, type of materials used, and production demands must be carefully assessed.

Ultimately, making an informed choice in selecting a plastic injection molding machine can lead to sustainable growth and innovation in product development, reflecting the significance of this technology in modern manufacturing practices. As we delve into the ten essential tips for making the right choice, it becomes evident that strategic planning and detailed knowledge are indispensable in navigating this complex decision-making process.

Understanding the Basics of Plastic Injection Molding Machines

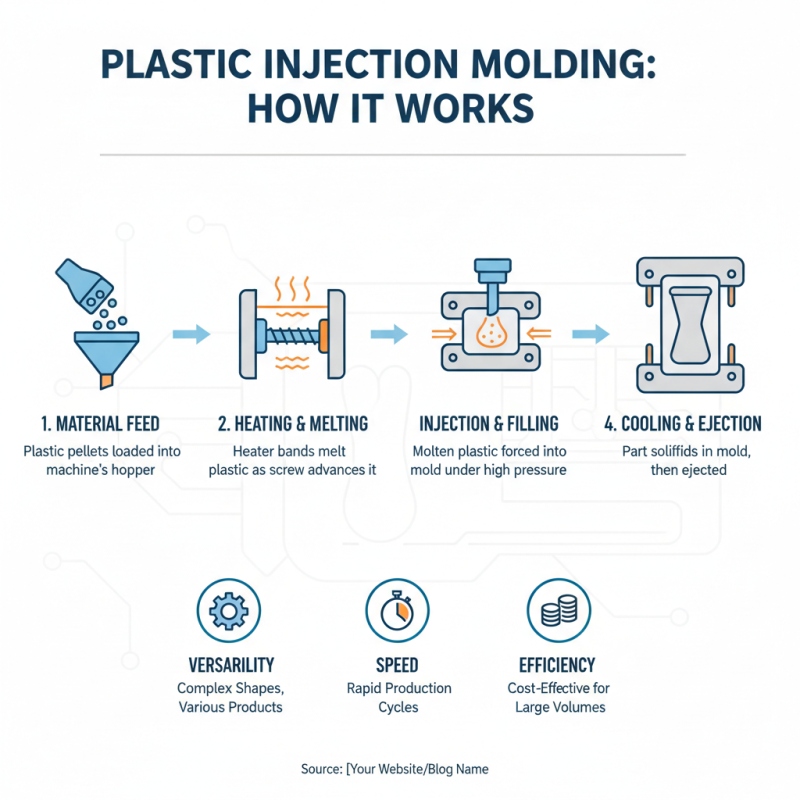

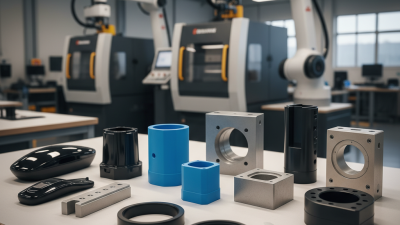

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic into a mold to create a variety of components and products. Understanding the basic principles behind plastic injection molding machines is crucial for making informed decisions when selecting the right equipment. These machines work by heating plastic pellets until they melt and then forcing the liquid plastic into a mold cavity using high pressure. The cooling and solidification process within the mold allows the finished product to take on the desired shape.

When choosing a plastic injection molding machine, several factors come into play. The size and capacity of the machine are pivotal, as they determine the volume of production and the complexity of the parts you can create. Additionally, the type of plastics you intend to use will influence your decision, as different materials may require specific temperatures and injection speeds for optimal results. It's also important to consider the machine's energy efficiency, ease of use, and maintenance requirements, as these factors will affect both operational costs and the overall productivity of your manufacturing process.

Key Factors to Consider When Selecting an Injection Molding Machine

When selecting a plastic injection molding machine, several key factors should be taken into account to ensure optimum performance and profitability. The first consideration is the type of materials you will be using. Different resins and plastics require specific machine capabilities; for example, thermoplastics generally need machines with higher injection speeds and pressures. According to a report by the American Injection Molding Institute, improper material selection can lead to a waste of up to 20% of production time due to inefficiencies and machine downtimes.

The size of the machine is another critical factor. It's essential to choose a machine that matches your production volume and product design. Large machines may provide the capacity for high-volume production, but if the parts are small and the production rate is low, energy costs may drive profitability down. Tip: Always calculate your expected cycle times and production quantities to ensure your machine can meet demand without unnecessary operational costs.

Additionally, consider the machine’s energy efficiency. With rising energy costs, opting for energy-efficient machines can offer significant savings over time. Data from industry studies show that energy-efficient models can reduce energy consumption by up to 30%. Tip: Look for machines that provide real-time energy monitoring features, as this will help you track usage and manage expenses effectively. By focusing on these critical factors, you can make an informed decision that aligns with your operational goals and budget.

Evaluating Machine Specifications and Capabilities for Your Needs

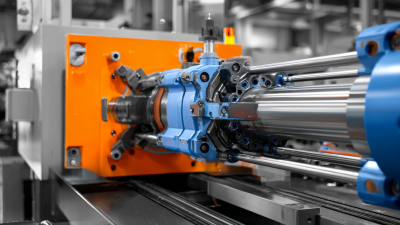

When selecting a plastic injection molding machine, it's crucial to evaluate the machine's specifications and capabilities to ensure it meets your production requirements. According to a recent report by the Plastics Industry Association, the injection molding market is projected to grow significantly, emphasizing the importance of investing in the right equipment. A machine's clamping force is one of the primary specifications to consider, as it directly affects the mold's ability to resist the pressure during the injection cycle. For most applications, a clamping force ranging from 100 to 500 tons is typical, but larger projects may require machines with much higher capabilities.

Another vital aspect is the machine's shot size, which refers to the amount of plastic injected into the mold per cycle. Choosing the correct shot size is essential for maintaining product quality and minimizing waste. According to industry data, optimizing shot size can lead to a 15-25% reduction in material usage. It's advisable to analyze your product design and production volume to align the shot size with your operational needs effectively.

Lastly, consider the machine's energy efficiency and speed. Advanced machines now incorporate features that enhance productivity while reducing energy consumption. Reports indicate that energy-efficient models can reduce operational costs by up to 30%. In summary, a thorough assessment of these specifications will help you find a plastic injection molding machine that not only fits your immediate needs but also supports long-term business growth.

Assessing the Importance of Energy Efficiency in Molding Machines

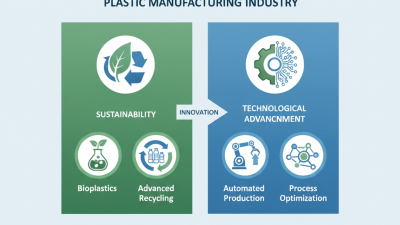

Energy efficiency plays a critical role in the selection of plastic injection molding machines, as it directly impacts both operational costs and environmental sustainability. With rising energy prices and increasing awareness of ecological footprints, manufacturers are now prioritizing energy-efficient machines not only to reduce expenses but also to enhance their corporate responsibility. An energy-efficient machine consumes less power during operation, which translates into lower electricity bills and a reduced carbon footprint, making it a smart choice for companies aiming to optimize profitability while adhering to environmental standards.

When evaluating the energy efficiency of molding machines, factors such as the technology used in the hydraulic system, the insulation of heating elements, and the ability to recycle energy should be considered. Machines that incorporate advanced technologies, such as servo motors or hybrid systems, often demonstrate significantly improved energy savings compared to traditional models. Furthermore, understanding the machine's energy consumption patterns through detailed performance specifications can aid businesses in making informed decisions that lead to long-term savings and operational efficiency. Adopting energy-efficient designs not only benefits manufacturers financially but also enhances their marketability as consumers increasingly favor environmentally conscious brands.

Comparing Manufacturers: Reliability, Support, and Warranty Options

When selecting a plastic injection molding machine, analyzing manufacturers' reliability, support, and warranty options is crucial for long-term success. A recent industry report indicates that nearly 60% of manufacturers prioritize reliability over other factors when choosing equipment, underscoring the importance of selecting a supplier with a proven track record. Reliability includes not only the durability of the machine but also the consistency of performance under varying production loads. Manufacturers should conduct thorough research, examining case studies and customer testimonials, to gauge the reliability of potential partners.

Support services are equally vital in the decision-making process. According to industry surveys, 45% of production delays can be attributed to machine downtime caused by inadequate technical support. This emphasizes the need for manufacturers to partner with suppliers that offer comprehensive support packages, including 24/7 technical assistance and readily available replacement parts. Furthermore, warranty options serve as a safety net, offering financial protection and peace of mind. A recent analysis shows that machines with extended warranties indicate manufacturers’ confidence in their products and can lead to substantial cost savings over the lifespan of the machine. By comparing these factors across different manufacturers, companies can make informed decisions that will enhance efficiency and profitability in their operations.

Comparison of Plastic Injection Molding Machine Features

Related Posts

-

2025 How to Choose the Best Plastic Injection Molding Machine for Your Needs

-

Top 10 Benefits of Injection Molding for Manufacturing Efficiency

-

10 Essential Tips to Optimize Your Plastic Injection Moulding Process Efficiency

-

Top Insights on Plastic Manufacturing Industry Trends and Innovations

-

Top Injection Molding Machine Trends to Watch in 2025

-

Top 10 Best Molded Parts for Your Manufacturing Needs in 2023

Our Promise to You

All products and services provided by Innovative Plastic Molders, Inc. will meet or exceed our customer's perceived requirements and expectations. We will listen and respond to what our customers are telling us in a timely and forthright manner.

ISO 9001:2015 CERTIFIED

© Copyright 2009 – Innovative Plastic Molders, Inc.

Website by Central 8 Marketing

Contact IPM

10451 Dog Leg Road Ste 200

Vandalia, OH 45377

Phone: 937.898.3775

Fax: 937.535.0640

Email: sale@endtheplastic.com