BLOG

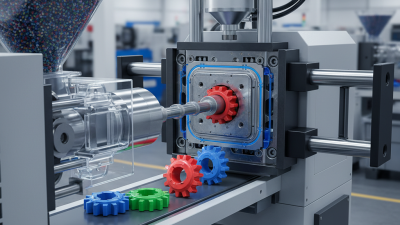

Top Benefits of Custom Plastic Injection Molding for Your Business Needs

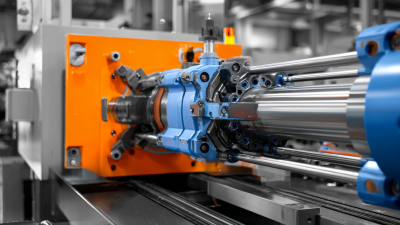

In the modern manufacturing landscape, businesses are constantly seeking innovative solutions that enhance their production efficiency and product quality. Custom plastic injection molding has emerged as a vital technique that not only meets the unique demands of various industries but also offers significant advantages over traditional manufacturing methods. As industry expert Dr. Emily Sanders, a distinguished figure in the field of polymer engineering, states, "Custom plastic injection molding provides unparalleled design flexibility and precision, allowing businesses to create products that perfectly align with their specifications."

The benefits of custom plastic injection molding extend beyond mere aesthetics; they encompass improved production speed, cost-effectiveness, and the ability to produce complex shapes that would be impossible with other manufacturing processes. This approach enables companies to optimize their supply chain, reduce material waste, and ultimately deliver high-quality products to their customers in a timely manner. By investing in custom plastic injection molding, businesses can harness the power of modern technology to ensure their growth and competitiveness in an ever-evolving market. As we delve deeper into the various benefits of this versatile manufacturing solution, it becomes clear that the strategic implementation of custom plastic injection molding can redefine a company’s operational capabilities and market presence.

Advantages of Custom Plastic Injection Molding in Production Efficiency

Custom plastic injection molding offers significant advantages in production efficiency that can greatly benefit businesses. Firstly, this process allows for high-volume production with minimal waste, as it utilizes precise molds to create parts that meet exact specifications. By employing automated machinery, companies can significantly reduce production time and improve cycle times. This efficiency not only accelerates the time-to-market for products but also helps in maintaining consistent quality across batches.

Moreover, the versatility of custom plastic injection molding means that businesses can easily modify designs and materials to suit specific needs without overhauling the entire production line. This adaptability allows companies to respond swiftly to changing market demands, ensuring they remain competitive.

Additionally, the use of advanced technologies in injection molding enables complex geometries and intricate designs that would be difficult or impossible to achieve with other manufacturing processes, thus further enhancing operational efficiency. Overall, these advantages make custom plastic injection molding an essential strategy for businesses looking to optimize their production processes.

Cost-Effectiveness of Custom Plastic Injection Molding in Manufacturing

Custom plastic injection molding has become a pivotal manufacturing process, particularly concerning cost-effectiveness. According to a recent report by Smithers Pira, companies that utilize custom injection molding can reduce overall production costs by up to 30% compared to traditional manufacturing methods. This significant cost savings can be attributed to the efficiency of producing large quantities of high-quality parts quickly and with minimal waste. Since the process allows for precise control over material usage, businesses can optimize their manufacturing costs while ensuring that each component meets the required specifications.

Moreover, the initial investment in injection molds can yield substantial long-term savings. Industry data indicates that, while the upfront costs for mold creation may seem high, the durability and reusability of these molds can lead to lower per-unit costs as production scales increase. In fact, as reported in the MIT Technology Review, companies can recoup their investment within just a few production cycles, especially when producing high volumes. This highlights the financial viability of custom plastic injection molding not only as a method to create parts but as a strategic investment that enhances operational efficiency and profitability.

Top Benefits of Custom Plastic Injection Molding for Your Business Needs

| Benefit | Description | Cost-Effectiveness |

|---|---|---|

| High Production Efficiency | Enables large volumes of parts to be produced quickly and with minimal waste. | Reduces labor and production time costs. |

| Design Flexibility | Allows for intricate designs that can be precisely manufactured. | Minimizes costs related to design changes during production. |

| Material Variety | Offers a wide range of plastics that can be used for different applications. | Enhances material selection, optimizing performance and cost. |

| Consistency and Quality | Ensures uniformity in product quality across large production runs. | Reduces rejection rates and associated costs. |

| Faster Time-to-Market | Accelerates the production process from design to delivery. | Minimizes costs related to delays in product launches. |

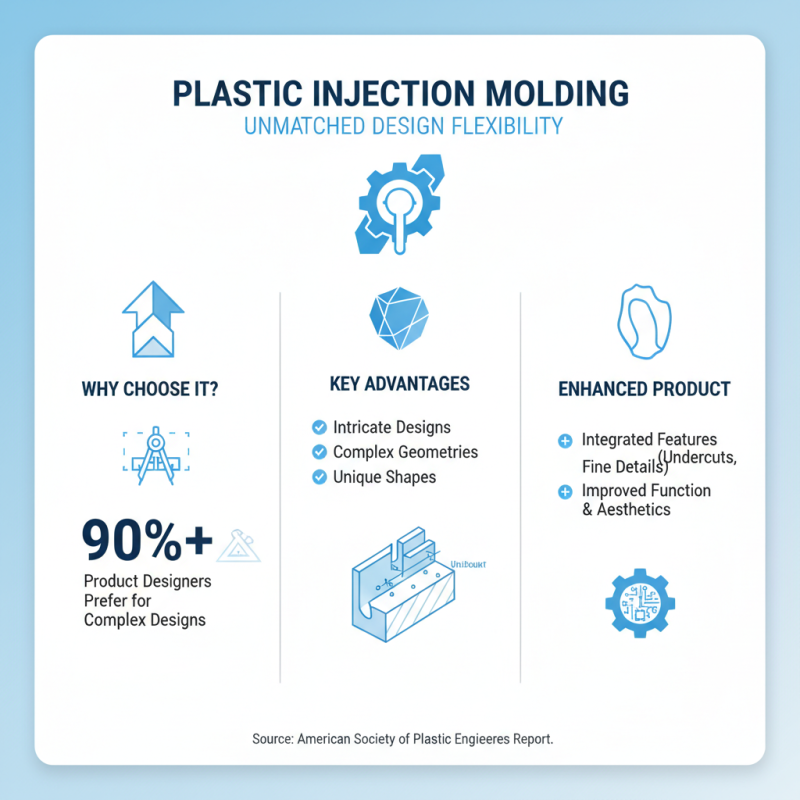

Impact of Custom Plastic Injection Molding on Design Flexibility

Custom plastic injection molding offers remarkable design flexibility, a central advantage for businesses looking to innovate and adapt. According to a report by the American Society of Plastic Engineers, over 90% of product designers choose injection molding due to its ability to produce intricate designs and complex geometries that are often unattainable with other manufacturing methods. This adaptability not only allows for unique shapes but also facilitates the integration of features like undercuts and fine details, which can enhance product functionality and aesthetics.

Additionally, custom molds can be tailored to specific project needs, enabling manufacturers to execute specialized designs that cater to diverse customer requirements. A study published by the injection Molding Association revealed that companies utilizing customized molds experienced a 25% reduction in production costs while also achieving a 40% faster time-to-market compared to traditional methods. This capability means that businesses can swiftly respond to market trends and consumer preferences, ensuring that they remain competitive in an ever-evolving landscape. As such, the impact of custom plastic injection molding on design flexibility is significant, making it a vital component in modern manufacturing strategies.

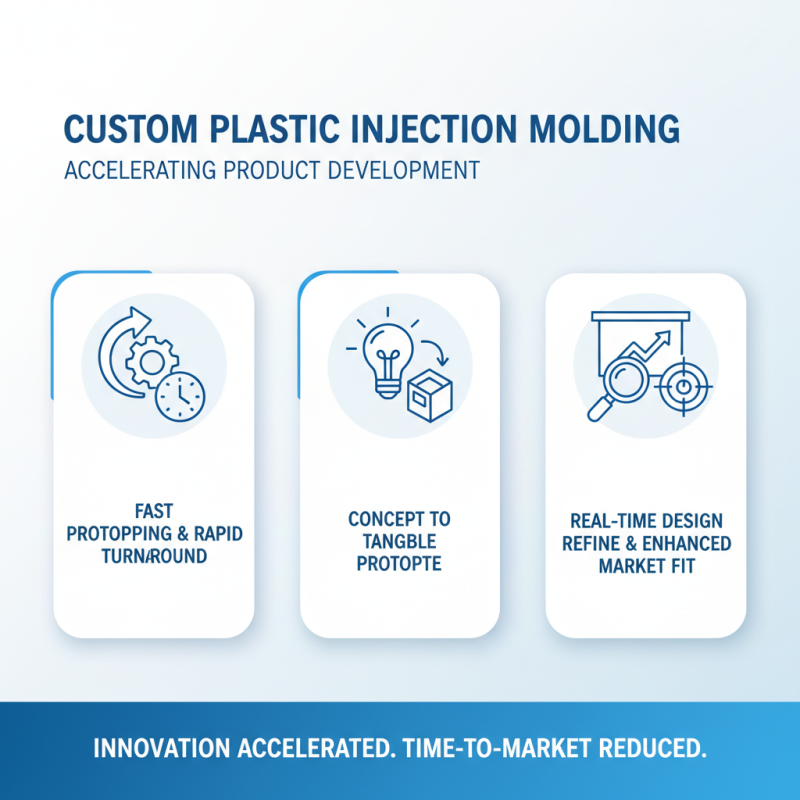

Fast Prototyping Capabilities with Custom Plastic Injection Molding

Custom plastic injection molding is revolutionizing the way businesses approach product development, particularly through its fast prototyping capabilities. This method allows companies to quickly turn concepts into tangible prototypes, significantly reducing the time from idea to implementation. With rapid turnaround times, engineers and designers can test and refine their designs in real time, enabling them to make informed decisions that enhance product performance and market fit.

Tips for effective fast prototyping with custom plastic injection molding include prefacing your design with thorough planning and modeling. Utilizing computer-aided design (CAD) software can help anticipate potential issues before the prototyping stage, saving time and resources. Additionally, collaborating closely with your molding partner can ensure better alignment of vision and expectations, ultimately leading to more accurate prototypes that can effectively represent the final product.

Another crucial tip is to prioritize material selection early on. Different plastics can yield varying characteristics in terms of strength, flexibility, and durability. By understanding the intended use of your product and selecting the appropriate material beforehand, you can significantly enhance the effectiveness of your prototyping process and ensure that the final production aligns perfectly with your vision. Adopting these strategies will optimize the benefits of custom plastic injection molding and set your business up for success.

Sustainability Benefits of Using Custom Plastic Injection Molding Techniques

Custom plastic injection molding is increasingly recognized for its sustainability benefits, making it an excellent choice for environmentally conscious businesses. One of the primary advantages is the ability to optimize material usage. Advanced techniques in injection molding allow manufacturers to create precise molds that minimize waste during production. This not only conserves resources but also reduces the overall carbon footprint associated with the manufacturing process.

Furthermore, the versatility of materials in custom plastic injection molding supports sustainability efforts. Many manufacturers are now using recycled and bio-based plastics, which help in reducing the demand for virgin materials and lower the environmental impact. This shift towards sustainable materials aligns with global efforts to reduce plastic pollution, ensuring that businesses can meet their corporate social responsibilities while still achieving their production goals. By embracing these eco-friendly practices, companies can enhance their brand image while contributing positively to the environment.

Top Benefits of Custom Plastic Injection Molding for Your Business Needs

The chart above illustrates the key benefits of custom plastic injection molding techniques, showcasing scores based on various dimensions that highlight how these methods can enhance efficiency, reduce waste, and offer design flexibility in business processes.

Related Posts

-

10 Essential Tips to Optimize Your Plastic Injection Moulding Process Efficiency

-

Top 10 Benefits of Custom Plastic Injection Molding for Your Business

-

Understanding the Plastic Injection Moulding Process for Efficient Manufacturing

-

The Future of Manufacturing How Injection Molding Companies are Revolutionizing Production Processes

-

Top 10 Benefits of Injection Molding for Manufacturing Efficiency

-

2025 Guide: How Custom Plastic Molding Drives $35 Billion Industry Growth

Our Promise to You

All products and services provided by Innovative Plastic Molders, Inc. will meet or exceed our customer's perceived requirements and expectations. We will listen and respond to what our customers are telling us in a timely and forthright manner.

ISO 9001:2015 CERTIFIED

© Copyright 2009 – Innovative Plastic Molders, Inc.

Website by Central 8 Marketing

Contact IPM

10451 Dog Leg Road Ste 200

Vandalia, OH 45377

Phone: 937.898.3775

Fax: 937.535.0640

Email: sale@endtheplastic.com