BLOG

How to Choose the Right Plastic Inc Company for Your Needs?

Choosing the right plastic inc company is crucial for your business. This decision impacts quality, cost, and delivery speed. Many options exist, but not all meet your specific needs. You may feel overwhelmed by the choices.

It is essential to consider several factors. Look for companies with a solid reputation in the industry. Check their product quality and customer service records. Explore their range of services. Plastic inc companies vary widely in what they offer. Some excel in custom fabrication, while others may focus on mass production.

Reflect on the long-term partnership potential. You want a provider that aligns with your vision. Failing to choose wisely can lead to poor outcomes and wasted resources. Researching thoroughly is the key to finding the right fit. Take your time and weigh all options. A thoughtful approach benefits your business in the long run.

Understanding Your Specific Plastic Needs and Requirements

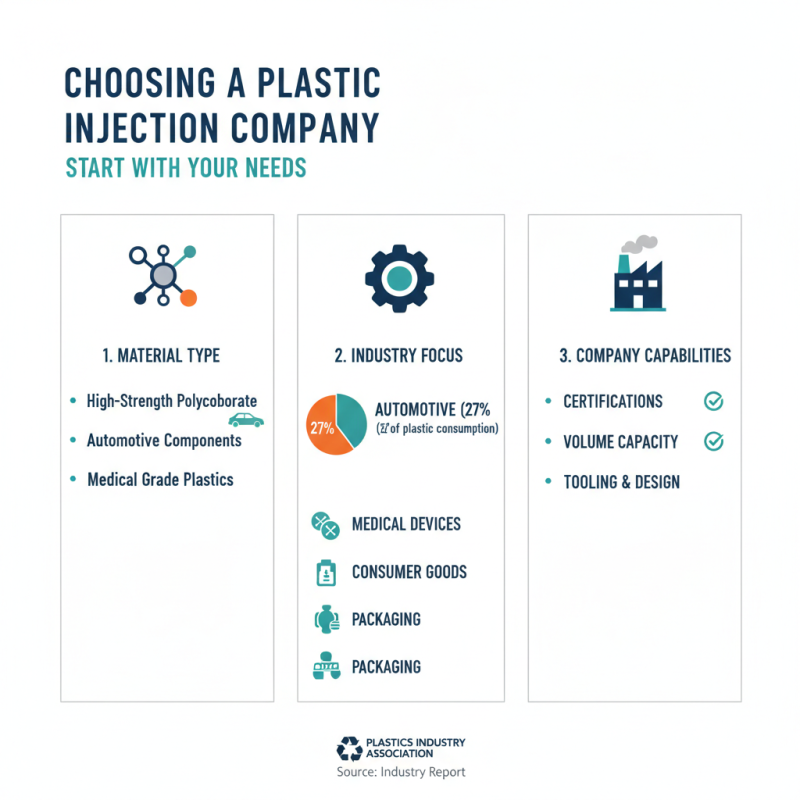

Choosing a plastic injection company starts with understanding your specific needs. The types of plastics you require can significantly affect your choice. For instance, if you're creating components for the automotive industry, you may need high-strength polycarbonate. The industry report from the Plastics Industry Association states that automotive applications account for 27% of total plastic consumption in manufacturing.

Another factor is the production volume. If you need high quantities, look for companies with robust manufacturing capabilities. A report from Mordor Intelligence indicates that nearly 60% of manufacturers prefer suppliers who can handle order fluctuations. Smaller companies might struggle to meet these demands.

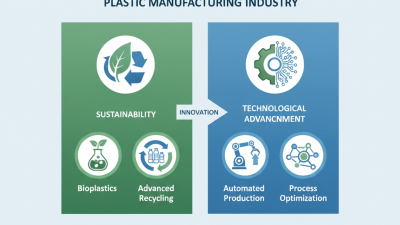

Don't forget about sustainability. Many clients are now prioritizing eco-friendly practices. According to a survey by McKinsey, 70% of consumers are willing to pay more for sustainable products. Thus, confirming a company’s commitment to sustainability can be crucial. While many suppliers claim to be sustainable, it’s essential to dig deeper and assess their actual practices. This will ultimately benefit your project and reflect positively on your brand's values.

Researching Plastic Inc Companies and Their Expertise

When researching plastic companies, focus on their expertise. Understanding their capabilities is essential. Many companies specialize in different sectors, such as automotive, medical, or consumer goods. Evaluating their portfolios can reveal reliability and quality. According to a recent industry report, over 40% of manufacturers regard material expertise as the top factor in selecting a plastic supplier.

Reviewing certifications matters. Certification ensures compliance with health and safety standards. Companies with ISO certifications usually maintain higher quality controls. However, some firms might possess outdated certifications. This gap can affect product reliability and safety. Research highlights that 25% of companies face challenges in maintaining updated certifications.

Examine their production technologies. Advanced techniques can improve efficiency and reduce waste. Yet, obtaining expertise in newer methods can take time. Some companies may lag behind. About 30% struggle with adopting sustainable practices in their production lines. Scrutinizing a company's willingness to innovate is critical. You want a partner who evolves with industry trends.

Evaluating Quality and Certifications of Plastic Products

When selecting a plastic injection company, evaluating the quality of their products is crucial. Certifications show a company's commitment to standards. Look for ISO certifications, as they indicate a strong quality management system. This ensures their products meet specific performance thresholds. If certifications are missing, question their quality assurance practices.

Tips: Always ask for samples. Testing the samples can reveal a lot about their manufacturing processes. It’s better to identify issues upfront. Don't ignore customer reviews. Past experiences highlight potential problems and strengths.

Consider the materials used in production. The quality of raw materials heavily influences the final product. Poor material choices can lead to weak or flawed products. Be cautious with companies that can't provide clear information about their materials. Trust your instincts. If something feels off about a company, dig deeper or look elsewhere.

Comparing Pricing and Service Offerings from Different Companies

When selecting a plastic injection molding company, pricing and service offerings are critical factors. Recent industry reports indicate that companies can vary significantly in pricing structures. Some providers offer lower costs at the expense of service quality, while others maintain higher prices due to superior materials and technology. For instance, basic mold services might start at $5,000, but intricate designs can exceed $50,000. This variance can be confusing for buyers.

It’s also vital to compare the range of services provided. Not every company will offer design assistance or support throughout production. A study found that 70% of clients value post-production services, such as logistics and assembly. Companies lacking these services might save money upfront but lead to higher costs later. Additionally, quality assurance practices can differ widely; some manufacturers implement rigorous testing, while others do not. This inconsistency can impact final product quality.

In considering these factors, it's essential to reflect on what truly meets your needs. Are lower prices more important than comprehensive services? Or is it worth investing in a company that aligns with your quality standards? Finding the right balance requires careful thought, as decisions made here can have long-term consequences on your project's success.

How to Choose the Right Plastic Inc Company for Your Needs?

| Service Type | Price Range | Lead Time | Minimum Order Quantity | Customer Support |

|---|---|---|---|---|

| Custom Molding | $5,000 - $20,000 | 4 - 6 weeks | 100 units | Phone & Email |

| Injection Molding | $10,000 - $50,000 | 6 - 8 weeks | 500 units | 24/7 Support |

| Blow Molding | $15,000 - $30,000 | 5 - 7 weeks | 300 units | Chat Support |

| Thermoforming | $2,500 - $15,000 | 3 - 5 weeks | 200 units | Email Support |

Reading Customer Reviews and Testimonials for Insightful Feedback

When selecting a plastic injection company, customer reviews and testimonials offer invaluable insights. According to recent industry studies, approximately 85% of customers rely on online reviews for their purchasing decisions. These reviews can highlight the strengths and weaknesses of companies, revealing patterns in customer satisfaction and product quality.

Reading feedback from previous clients helps identify potential red flags. A significant percentage of reviews may point out issues regarding delivery times or product consistency. For instance, a particular company might receive consistent complaints about delays. On the other hand, positive testimonials often emphasize durability and customer service. These insights can guide your decision-making process effectively.

It’s important to analyze the context of reviews. A company may have a high overall rating but frequent comments about poor communication. This discrepancy warrants reflection. Furthermore, industry reports indicate that 70% of buyers prefer companies with transparent feedback, where both positive and negative experiences coexist. Balancing these perspectives can lead to a more comprehensive understanding of a company’s reliability and performance in the plastic injection sector.

Customer Feedback Analysis of Plastic Inc Companies

Related Posts

-

Effective Ways to Reduce Plastic Waste in Your Business Operations

-

What is Plastic Production and Its Impact on the Environment?

-

How to Choose the Right Molding Plastic for Your Next Project

-

How to Choose the Right Plastic Company for Your Manufacturing Needs

-

Top Insights on Plastic Manufacturing Industry Trends and Innovations

-

Exploring the Future of Injection Tooling Innovations and Trends

Our Promise to You

All products and services provided by Innovative Plastic Molders, Inc. will meet or exceed our customer's perceived requirements and expectations. We will listen and respond to what our customers are telling us in a timely and forthright manner.

ISO 9001:2015 CERTIFIED

© Copyright 2009 – Innovative Plastic Molders, Inc.

Website by Central 8 Marketing

Contact IPM

10451 Dog Leg Road Ste 200

Vandalia, OH 45377

Phone: 937.898.3775

Fax: 937.535.0640

Email: sale@endtheplastic.com