BLOG

How to Choose the Right Plastic Company for Your Manufacturing Needs

Choosing the right plastic company for your manufacturing needs is a critical decision that can significantly impact the efficiency, quality, and success of your production processes. As businesses increasingly rely on plastic components for a wide range of applications, finding a reputable and capable plastic company becomes essential. In the words of industry expert Dr. Emily Thompson, a leading authority in plastic manufacturing, “The effectiveness of your supply chain often hinges on the quality of the plastic company you choose; it should be a partnership built on trust, expertise, and innovation.”

When evaluating potential plastic companies, it's vital to consider factors such as their experience, technology capabilities, and commitment to quality. The landscape of the plastic industry has evolved, with advancements in sustainable practices and innovative materials reshaping the market. Understanding these dynamics is key to making an informed choice. By collaborating with a well-established plastic company, manufacturers can ensure they remain competitive while meeting ever-growing consumer demands for sustainability and performance.

Ultimately, the selection process should be thorough and strategic, leading to a long-term partnership that aligns with your manufacturing objectives. By taking the time to assess various options, companies can secure a plastic company that not only meets their immediate needs but also contributes to their sustained growth and success in an increasingly complex marketplace.

Identifying Your Manufacturing Requirements and Specifications

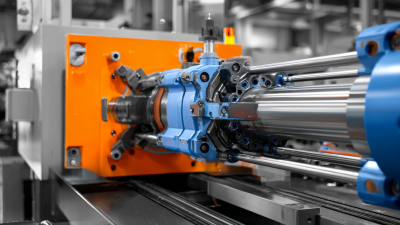

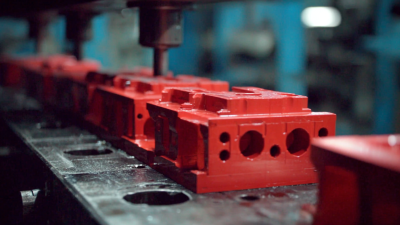

When selecting the right plastic company for your manufacturing needs, it is crucial to first identify your specific manufacturing requirements and specifications. Understanding your project's scope is the foundation for effective collaboration with a plastic manufacturer. Consider the type of plastic materials needed, the desired physical properties, and how these materials will be processed. For instance, whether you're looking for injection molding, extrusion, or blow molding will significantly influence which company you should partner with. Clearly defining the end-use of the product also helps in determining the appropriate standards for durability, flexibility, and resistance to various environmental factors.

Furthermore, engaging with potential manufacturers involves thoroughly discussing your project timelines, production volumes, and quality control processes. This step is essential to ensure that the company can meet your deadlines and maintain consistent quality throughout production. Additionally, requesting samples and case studies can provide insight into the manufacturer’s capabilities and experience in your industry. By clearly articulating your requirements and maintaining open lines of communication, you will ensure a more productive relationship and a smoother manufacturing process.

Manufacturing Requirements Comparison for Plastic Companies

Researching Potential Plastic Companies and Their Specializations

When selecting a plastic company for your manufacturing needs, thorough research into potential candidates and their areas of specialization is crucial. Start by identifying the specific type of plastic products you require, as different companies may excel in various plastic materials or processes, such as injection molding, blow molding, or extrusion. Understanding these distinctions will help narrow down your search to companies that are best positioned to meet your needs.

Additionally, consider examining the company’s portfolio and case studies to gain insight into their capabilities and past performance. Look for companies that have experience in your industry, as they will better understand the unique challenges and requirements you may face. Engaging in discussions with past clients or reading reviews can further inform you about the reliability, quality, and customer service of each potential company. Taking these steps will ensure that you choose a plastic manufacturer that aligns with both your technical specifications and business values.

Evaluating Quality Control Processes and Certifications

When selecting a plastic company for your manufacturing needs, it's crucial to closely evaluate their quality control processes and certifications. Quality control not only ensures that the products meet specific standards but also mitigates the risk of defects that can lead to production delays or increased costs. A robust quality control system should include regular inspections, standardized testing procedures, and clear documentation. Look for companies that employ qualified personnel who are trained in quality assurance practices and are dedicated to maintaining industry standards.

Tips for evaluating quality control processes include asking for certifications such as ISO 9001, which demonstrates that the company has a systematic approach to quality management. Additionally, inquire about their quality assurance protocols, including how they monitor and document their processes. A reputable manufacturer should readily share their quality control measures and provide insight into their continual improvement strategies.

Furthermore, assess how the company responds to quality issues. Their approach to handling defects or customer complaints can reveal a lot about their commitment to maintaining high standards. A strong commitment to quality often reflects a company's overall reliability and dedication to customer satisfaction, making them a worthy partner for your manufacturing needs.

Comparing Cost Structures and Pricing Models

When selecting a plastic company for your manufacturing needs, understanding their cost structures and pricing models is crucial. Different companies may adopt various strategies, including tiered pricing, fixed costs, or variable costs, each affecting the overall expenditure of your project. For instance, a company that uses a tiered pricing model may offer lower rates for bulk orders, which can significantly impact your budget if you plan to scale production. On the other hand, fixed costs can provide predictability, but may also limit flexibility if project requirements change over time.

Another important aspect to consider is the transparency of the pricing model. A company that clearly outlines its cost breakdown—covering materials, labor, overhead, and additional fees—allows for more effective budget management. Comparing these structures across different companies can reveal not only the immediate costs but also the long-term implications of each model. Ultimately, selecting a partner with a pricing strategy that aligns with your operational goals will help ensure a smoother manufacturing process and better financial outcomes.

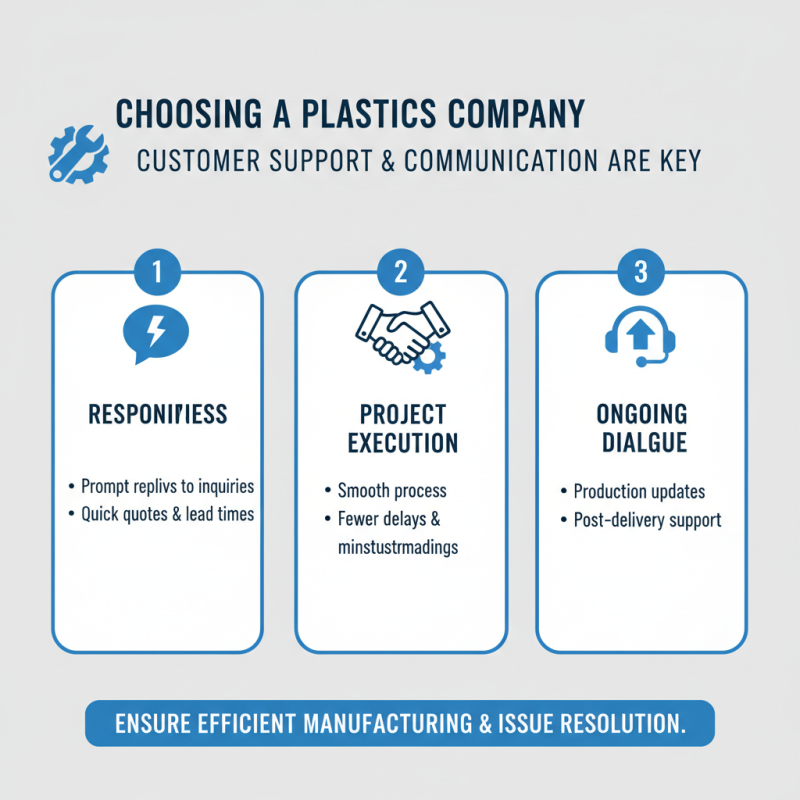

Assessing Customer Support and Communication Capabilities

When selecting a plastic company for your manufacturing needs, assessing customer support and communication capabilities is crucial. Effective communication can make the difference between a smooth project execution and potential delays or misunderstandings. Look for companies that prioritize responsiveness; prompt replies to inquiries indicate a high level of customer support that can be essential throughout the manufacturing process. This includes not only initial quotes and leads but also ongoing dialogue during production and after delivery, ensuring that any issues are addressed efficiently.

Moreover, consider the tools and channels utilized by the company for communication. A company that leverages modern communication platforms can facilitate more effective interactions. Whether through email, phone calls, or project management software, the ability to communicate effectively and transparently fosters a collaborative atmosphere. Additionally, inquire about the availability of support personnel throughout the project duration and after-sales service to ensure that help is always at hand, should questions or concerns arise. Ultimately, strong customer support and communication can significantly enhance your manufacturing experience, leading to better outcomes and long-term partnerships.

Related Posts

-

Top Injection Molding Machine Trends to Watch in 2025

-

10 Essential Tips to Optimize Your Plastic Injection Moulding Process Efficiency

-

Top 10 Molding Services: Choosing the Right Provider for Your Project

-

10 Best Injection Molded Parts for Your Manufacturing Needs

-

Understanding the Role of Plastic Injection Companies in Sustainable Manufacturing Practices

-

Exploring the Future of Injection Tooling Innovations and Trends

Our Promise to You

All products and services provided by Innovative Plastic Molders, Inc. will meet or exceed our customer's perceived requirements and expectations. We will listen and respond to what our customers are telling us in a timely and forthright manner.

ISO 9001:2015 CERTIFIED

© Copyright 2009 – Innovative Plastic Molders, Inc.

Website by Central 8 Marketing

Contact IPM

10451 Dog Leg Road Ste 200

Vandalia, OH 45377

Phone: 937.898.3775

Fax: 937.535.0640

Email: sale@endtheplastic.com