BLOG

How to Choose the Best Custom Plastic Molding for Your Project

In the world of manufacturing, the significance of custom plastic molding cannot be overstated. According to a report by MarketsandMarkets, the global custom plastic molding market is projected to reach $370 billion by 2025, growing at a CAGR of 5.7%. This growth reflects the rising demand for precision-engineered plastic components across various industries, including automotive, medical, and consumer electronics.

Expert insights emphasize the importance of careful selection in custom plastic molding projects. Dr. Jonathan Parker, a leading figure in the plastics industry, notes, "Choosing the right molding process can make or break your project's success." Factors like material selection, production volume, and design specifications must be meticulously evaluated. However, many companies overlook these aspects. This often leads to costly errors and production delays, highlighting a common area for improvement in project planning.

Navigating the options in custom plastic molding can be daunting. The industry’s diversity presents both opportunities and challenges. Every decision impacts product quality and cost-efficiency. It's crucial to address these complexities head-on. A reflective approach can identify potential issues early, ensuring a smoother development process.

Identifying Your Project Requirements for Custom Plastic Molding

Identifying your project requirements for custom plastic molding is crucial for a successful outcome. Understanding the specific needs of your project can save time and resources. According to industry reports, nearly 70% of projects fail due to improper material selection. This can highlight the importance of thorough planning.

Set clear goals for functionality and aesthetic requirements. Consider the end-use of the product. For instance, if your project involves components for automotive applications, you might need materials that withstand high temperatures and resist chemicals. Choose between injection molding and blow molding based on your volume and complexity requirements.

Tips: Always conduct a feasibility analysis early in the design process. Engage with engineers to explore potential manufacturing challenges. Testing prototypes can reveal insights into material behavior under stress. Remember, each project's unique demands require a tailored approach. A “one-size-fits-all” mentality can lead to costly reworks and delays. Most importantly, remain open to feedback throughout the process, as it can refine your final product significantly.

Exploring Different Types of Plastic Molding Techniques Available

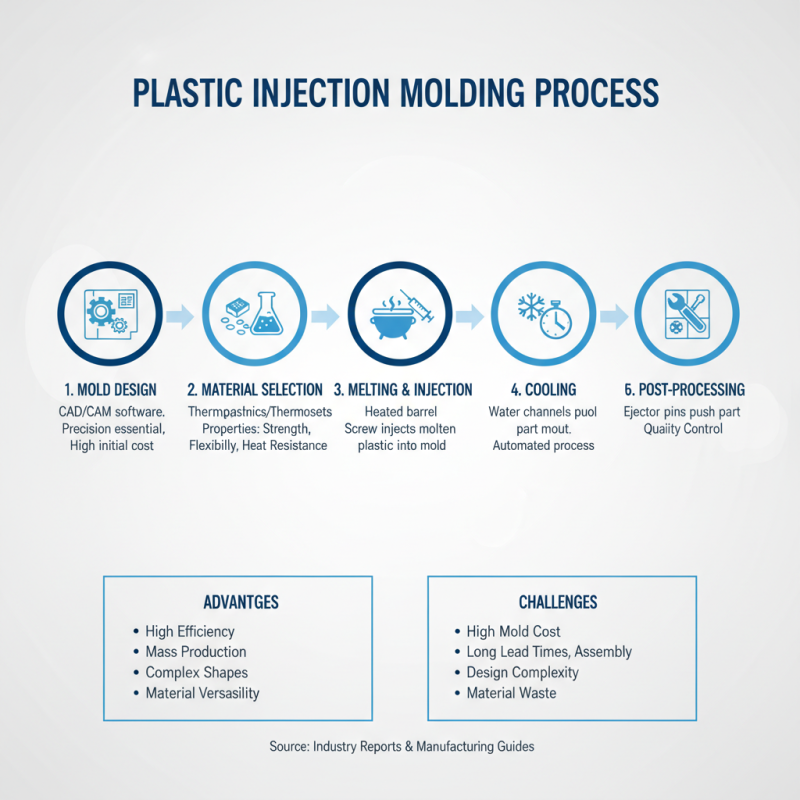

When selecting a plastic molding technique, it's essential to understand the various options available. Injection molding is one of the most popular methods. It offers precision and high efficiency for mass production. This technique is great for creating complex shapes. However, designing molds can be costly and time-consuming. If you're not careful during this phase, you might face delays that could affect your project timeline.

Another technique to consider is blow molding. This approach is ideal for creating hollow plastic parts, such as bottles. It typically requires less energy than injection molding but has limitations on design complexity. The process can lead to uneven wall thickness if not done correctly. This might require adjustments and trials, which can be frustrating.

Rotational molding is another option. This method is suited for large, hollow objects. It allows for greater flexibility in design. However, the cycle time is often longer. If you need a quick turnaround, this could be a drawback. Each technique has its pros and cons. Evaluating your project’s specific needs is crucial. Don't forget to consider factors like material compatibility and production volume.

Evaluating Design Considerations for Successful Molding Projects

Choosing the right custom plastic molding for your project requires careful design evaluation. Start by understanding the end use of the product. Consider its strength, flexibility, and appearance. Each of these factors will dictate the type of material and molding process you choose.

Tips: Focus on the design specifications. They should align with your project goals. Are there specific measurements or shapes that need precision? Don’t forget to think about the weight of the final product, as this can affect transportation and usability.

Another consideration involves the production volume. Will you need a single prototype or thousands of units? High-volume production may lead you to different molding techniques, like injection molding. Be aware, however, that larger production runs can have upfront costs. Sometimes, the investment might not show immediate returns.

Tips: Prototype early. This allows you to identify potential design flaws. It's often easier to make changes during the prototype phase than later. Discuss with your team how design complexity can impact manufacturing. Simple designs can often save time and money. Keep an open mind; adjustments may be necessary to optimize your project.

Selecting the Right Material for Your Custom Plastic Components

Selecting the right material for custom plastic components is crucial. Different applications require specific properties. For example, a report by the Plastic Industry Association indicates that ABS is widely used for its toughness and impact resistance. It’s a great choice for products needing durability.

However, not all projects benefit from the same material. Polycarbonate is another popular option, known for its clarity and high strength. It is often used in safety glasses and protective gear. But, it can be more expensive and less flexible. This can lead to overspending if the application doesn't warrant it.

Another key factor is the environmental impact. Many manufacturers are shifting towards biodegradable options. According to the Bioplastics Market Report, the demand for bioplastics is expected to grow by 15% annually. This push reflects changing consumer preferences. It is essential to evaluate if switching to an environmentally friendly material suits the project's goals. In summary, careful consideration of materials can steer projects towards success, even when choices feel overwhelming.

Material Selection for Custom Plastic Molding

Comparing Costs and Lead Times in Custom Plastic Molding Services

When selecting custom plastic molding services, understanding costs and lead times is crucial. Different manufacturers may offer varying prices. Factors include material type, complexity, and production volume. For instance, intricate designs often increase the cost, while simpler molds may be more economical.

Lead times can vary significantly. Some companies promise quick turnaround, but this may come at a premium. It's essential to communicate your deadlines clearly. Sometimes, rushing the process can lead to errors. A fast service might mean sacrificing quality. Evaluate potential trade-offs in quality versus speed in your decision-making.

Be prepared for unexpected challenges. For example, revisions after initial prototypes can delay your timeline. Always factor in potential adjustments in your planning. Seeking quotes from multiple suppliers is beneficial. This allows for a clearer picture of average costs and standard lead times in the industry.

How to Choose the Best Custom Plastic Molding for Your Project - Comparing Costs and Lead Times in Custom Plastic Molding Services

| Molding Type | Estimated Cost ($ per unit) | Lead Time (Weeks) | Material Options | Recommended Applications |

|---|---|---|---|---|

| Injection Molding | $0.50 - $3.00 | 2-6 | ABS, Polycarbonate, PVC | Consumer Products, Automotive Parts |

| Blow Molding | $1.00 - $5.00 | 3-8 | Polyethylene, Polypropylene | Bottles, Containers |

| Rotational Molding | $2.00 - $10.00 | 4-12 | Polyethylene, Nylon | Large Hollow Parts, Tanks |

| Compression Molding | $1.50 - $6.00 | 3-7 | Elastomers, Thermoplastics | Seals, Gaskets |

| Thermoforming | $0.50 - $2.00 | 1-4 | Polystyrene, PVC | Packaging, Trays |

Related Posts

-

2025 Guide: How Custom Plastic Molding Drives $35 Billion Industry Growth

-

2025 How to Choose the Best Plastic Injection Molding Machine for Your Needs

-

Top 10 Benefits of Custom Plastic Injection Molding for Your Business

-

Top Benefits of Custom Plastic Injection Molding for Your Business Needs

-

Why Custom Injection Molding is Key to Streamlining Your Manufacturing Process

-

Exploring the Future of Injection Tooling Innovations and Trends

Our Promise to You

All products and services provided by Innovative Plastic Molders, Inc. will meet or exceed our customer's perceived requirements and expectations. We will listen and respond to what our customers are telling us in a timely and forthright manner.

ISO 9001:2015 CERTIFIED

© Copyright 2009 – Innovative Plastic Molders, Inc.

Website by Central 8 Marketing

Contact IPM

10451 Dog Leg Road Ste 200

Vandalia, OH 45377

Phone: 937.898.3775

Fax: 937.535.0640

Email: sale@endtheplastic.com