BLOG

2025 How to Choose the Best Plastic Injection Molding Machine for Your Needs

Choosing the right plastic injection molding machine is crucial for manufacturers looking to optimize production efficiency, cost-effectiveness, and product quality. With the market offering a diverse array of machines, understanding the specific needs of your operation can greatly enhance the decision-making process. The year 2025 presents a unique set of industry challenges and opportunities, making it essential for businesses to select machinery that aligns with their strategic goals and production requirements.

As companies explore the features and capabilities of different plastic injection molding machines, they must consider factors such as material compatibility, clamping force, and cycle time. Each of these components plays a pivotal role in determining the overall performance and output quality of the final products. In a landscape where technological advancements are on the rise, comprehending the intricacies of these machines is paramount for ensuring that your investment pays off in efficiency and effectiveness.

Ultimately, the right plastic injection molding machine can significantly impact a company's bottom line and competitive edge in the market. As manufacturers navigate this critical decision, they must take the time to analyze their specific applications, production volumes, and long-term operational goals to invest in the machine that best meets their needs.

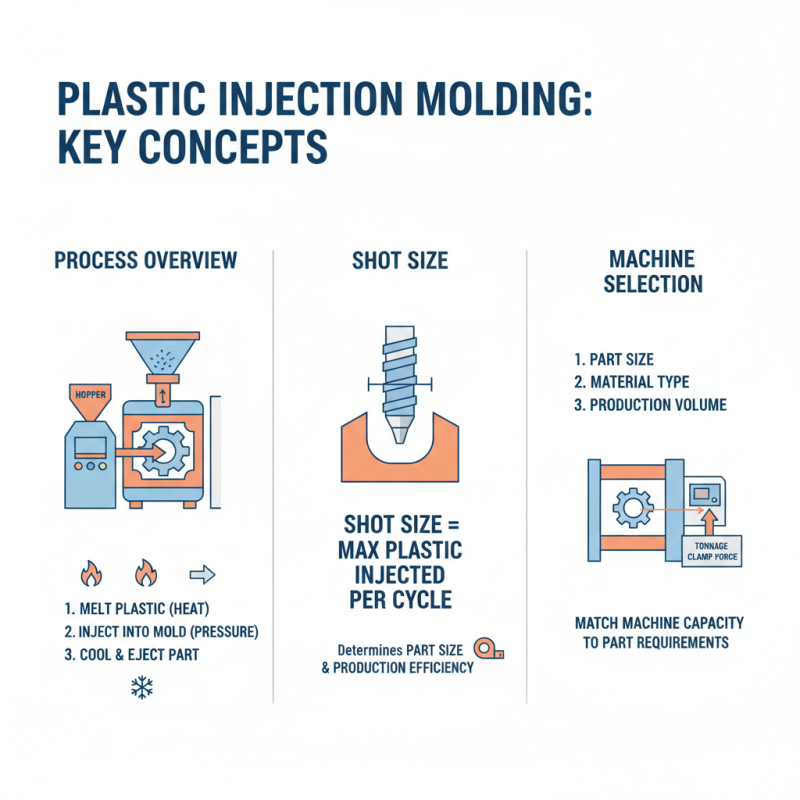

Understanding Plastic Injection Molding: Key Concepts and Terminology

Plastic injection molding is a manufacturing process that involves the creation of molten plastic, which is then injected into a mold to form a specific shape. Understanding the key concepts and terminology related to this process is essential for anyone looking to choose the right injection molding machine. One fundamental term is "shot size," which refers to the amount of plastic material that can be injected at one time. This measurement is crucial as it determines the size of the parts that can be produced and influences production efficiency.

Another important concept is "clamping force," which is the pressure required to keep the mold closed during the injection process. A machine with insufficient clamping force may lead to defects in the molded parts due to the mold opening under pressure. Additionally, terms like "cycle time," which indicates the total time required to complete one cycle of injection and cooling, play a critical role in assessing a machine's productivity. By understanding these key terms, manufacturers can make informed decisions about the specific needs of their production process and choose the injection molding machine that best fits their requirements.

Identifying Your Production Needs: Volume, Size, and Type of Parts

When selecting the best plastic injection molding machine, it's essential to begin by identifying your production needs. One of the critical factors to consider is the volume of production required. High-volume production may necessitate a machine with a larger clamping force and faster cycle times, as well as capabilities to handle continuous operations efficiently. Conversely, for lower volume productions, a more versatile machine that can easily switch between different jobs may be sufficient, allowing for better flexibility in manufacturing.

Size and type of parts are also crucial elements in the decision-making process. The dimensions of the parts you plan to produce will determine the size and clamping capacity of the injection molding machine. Larger or more complex parts may require a machine with greater injection capacity and a larger mold size. Additionally, consider the type of materials you plan to use, as different machines may have varying levels of compatibility with certain plastics. Understanding the specific requirements for your parts can lead to selecting a machine that not only meets production goals but also enhances efficiency and reduces waste.

2025 Plastic Injection Molding Machine Selection

Evaluating Machine Specifications: Clamping Force, Shot Size, and Speed

When selecting a plastic injection molding machine, evaluating the machine's specifications is crucial for meeting your production needs. Three of the most significant parameters to consider are clamping force, shot size, and speed. Clamping force is the force used to keep the mold closed during the injection process. According to industry standards, the required clamping force can be approximately estimated using the formula: Clamping Force (tons) = Projected Area (cm²) x Material Injection Pressure (bar). For typical applications, this means that a mold with a projected area of 500 cm² for a material requiring 60 bar pressure would need around 30 tons of clamping force. Ensuring that the machine’s clamping force aligns with these calculations is essential for operational efficiency and product quality.

Shot size, the volume of material that the machine can inject in a single cycle, directly affects the productivity of your operations. The shot size typically should be 10-15% larger than the calculated shot volume of your part to account for material swell and ensure complete filling. For instance, if your part requires a shot volume of 50 cm³, choosing a machine with a shot size of at least 55 cm³ would be advisable. Additionally, selecting a machine with faster injection speeds can improve cycle times and overall productivity. Industry reports indicate that machines with injection speeds exceeding 200 mm/s can enhance precision and reduce cycle time by as much as 20% in certain applications. Therefore, balancing these parameters carefully will lead to a more effective production process, optimizing both speed and quality in manufacturing.

Considering Energy Efficiency and Cost of Operation

When selecting a plastic injection molding machine, energy efficiency and cost of operation are pivotal factors to consider. According to a 2022 report by the International Energy Agency, industrial facilities account for nearly 40% of global energy consumption, with injection molding machines being significant contributors due to their energy-intensive processes. Choosing a machine that employs advanced energy-saving technologies can reduce operational costs significantly. For instance, machines equipped with servo motors can offer energy savings of up to 50% compared to traditional hydraulic machines, making them an attractive option for manufacturers looking to enhance their bottom line.

Furthermore, understanding the total cost of ownership (TCO) is essential in the selection process. A study from the Plastics Industry Association emphasizes the importance of factoring in not just the initial purchase price, but also the costs associated with energy consumption, maintenance, and downtime. Energy-efficient machines may have a higher upfront cost, but the reduced energy bills and lower maintenance needs can lead to a return on investment (ROI) in a relatively short period. Therefore, buyers must assess these long-term financial impacts alongside immediate costs to ensure they are choosing a machine that meets their operational and sustainability goals effectively.

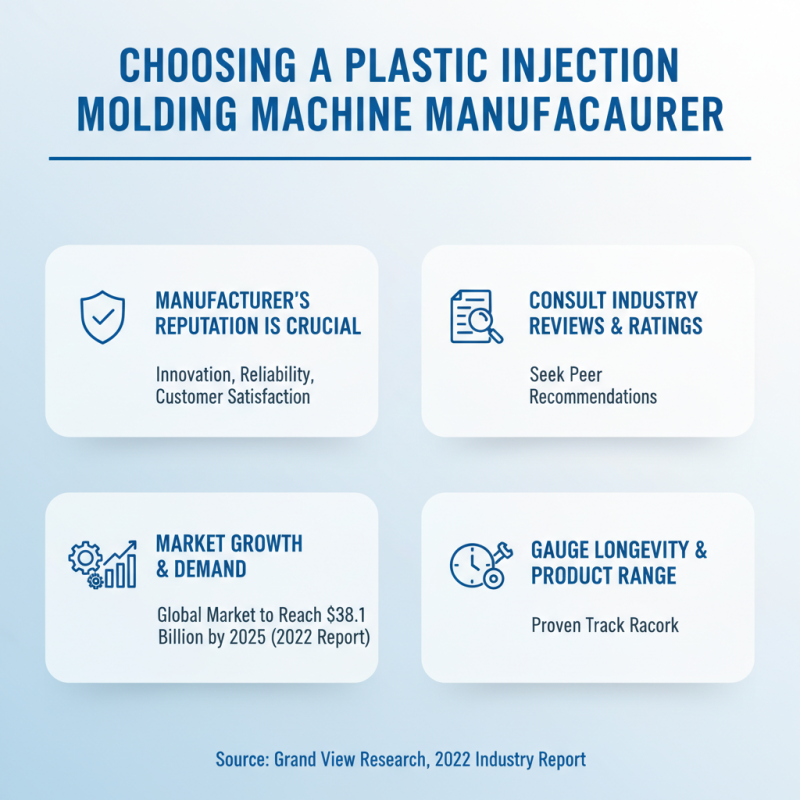

Assessing Manufacturer Reputation and After-Sales Support Options

When choosing the best plastic injection molding machine for your needs, assessing the manufacturer’s reputation is crucial. According to a 2022 industry report by Grand View Research, the global injection molding market is projected to reach $388.1 billion by 2025, reflecting the increasing demand for high-quality machinery. A reputable manufacturer typically has a proven track record of innovation, reliability, and customer satisfaction. It’s essential to consult industry reviews and ratings, as well as seek recommendations from peers within the sector. The health of a manufacturer’s reputation can often be gauged by their longevity in the industry and the extent of their product offerings.

After-sales support is another critical factor in your decision-making process. The complexity of injection molding machines means that robust support structures are vital. A study from Allied Market Research highlights that 80% of manufacturers value after-sales service when selecting a supplier, emphasizing the significance of effective technical support and maintenance. Timely assistance can minimize downtime and enhance productivity. Ensure the manufacturer provides comprehensive training, easy access to spare parts, and responsive technical support as part of their service package.

Tips: When evaluating a potential manufacturer, inquire about their customer service response times and available support channels. Additionally, consider looking for user testimonials or case studies that showcase the manufacturer’s ability to resolve issues effectively. Prioritize companies that offer customer-centric services, ensuring you receive the best support throughout the machine's lifecycle.

Related Posts

-

The Future of Manufacturing How Injection Molding Companies are Revolutionizing Production Processes

-

Top Injection Molding Machine Trends to Watch in 2025

-

Exploring the Future of Injection Molding Companies: Innovations and Trends in Manufacturing

-

How to Optimize the Injection Moulding Process for Better Efficiency and Quality

-

2025 Guide: How Custom Plastic Molding Drives $35 Billion Industry Growth

-

Exploring the Future of Injection Tooling Innovations and Trends

Our Promise to You

All products and services provided by Innovative Plastic Molders, Inc. will meet or exceed our customer's perceived requirements and expectations. We will listen and respond to what our customers are telling us in a timely and forthright manner.

ISO 9001:2015 CERTIFIED

© Copyright 2009 – Innovative Plastic Molders, Inc.

Website by Central 8 Marketing

Contact IPM

10451 Dog Leg Road Ste 200

Vandalia, OH 45377

Phone: 937.898.3775

Fax: 937.535.0640

Email: sale@endtheplastic.com