BLOG

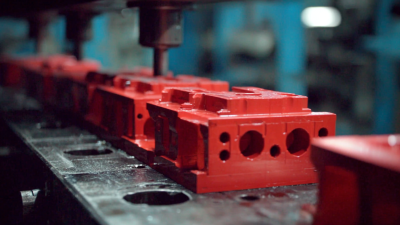

2026 Best Innovations in Plastic Production Technologies and Trends?

The landscape of plastic production is undergoing a significant transformation. Innovations in production technologies are reshaping the industry, responding to environmental concerns and market demands. According to a 2023 report by PlasticsEurope, global plastic production reached over 368 million metric tons. This figure highlights the industry's enormity and the urgent need for sustainable practices.

Emerging trends in plastic production are increasingly focused on recycling and bioplastics. A study by the Ellen MacArthur Foundation indicates that if current trends continue, plastic waste could outweigh fish in the ocean by 2025. Therefore, the race for advancements is critical. Innovations like digestible plastics and advanced recycling technologies are pivotal. Companies are investing heavily to accommodate rising eco-conscious consumer demands.

Despite these advancements, challenges remain. Not all innovations achieve commercial viability, and many processes are still energy-intensive. The industry must continue to reflect on its practices. Sustainability cannot be an afterthought; it must drive innovation in plastic production. As the world pushes for greener solutions, the success of these innovations will depend on effective implementation and genuine commitment across the sector.

Emerging Technologies Revolutionizing Plastic Production in 2026

The landscape of plastic production is evolving rapidly in 2026. Emerging technologies are leading the charge, reshaping how plastics are manufactured. One notable trend is bioplastics. These materials, derived from renewable sources, account for nearly 20% of the global plastic market today. Reports suggest that bioplastics could replace conventional plastics significantly by 2030.

Another significant development is the adoption of digital technologies. Industry 4.0 is transforming production processes. Smart factories use IoT sensors to optimize efficiency, reducing waste by up to 30%. However, this shift comes with challenges. Many small manufacturers struggle with the high costs of technological upgrade.

Recycling technology also sees a surge. Advanced sorting systems now improve recycling rates. Yet, the industry still faces hurdles. The contamination of recycled materials limits their usability. Companies must invest in cleaner production processes to address these issues. These innovations present opportunities, but they require consistent efforts to make sustainable practices the norm.

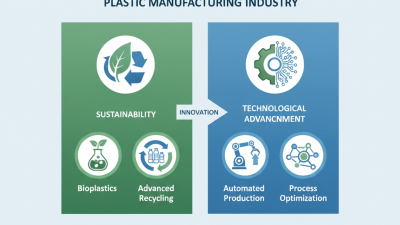

Sustainable Practices Shaping the Future of Plastic Manufacturing

Sustainable practices are redefining plastic manufacturing. Innovations are emerging to reduce waste and enhance recycling. In recent years, companies have explored bio-based materials. These alternatives are made from renewable sources. They offer a promising path to greener production.

Recycling methods are also advancing. New technologies are improving the efficiency of recycling processes. Mechanical recycling remains popular, but chemical recycling is gaining attention. This technique breaks plastics back into raw components. It opens doors for creating new materials from what was once waste. Yet, many challenges remain. Contamination in recycling streams is a persistent issue.

Moreover, using less plastic is a growing trend. Many manufacturers are rethinking designs to minimize material use. Lightweighting, for instance, can lower production costs and reduce environmental impact. Nonetheless, the balance between functionality and sustainability is tricky. Brands must address these complexities while advancing their eco-initiatives.

2026 Best Innovations in Plastic Production Technologies and Trends

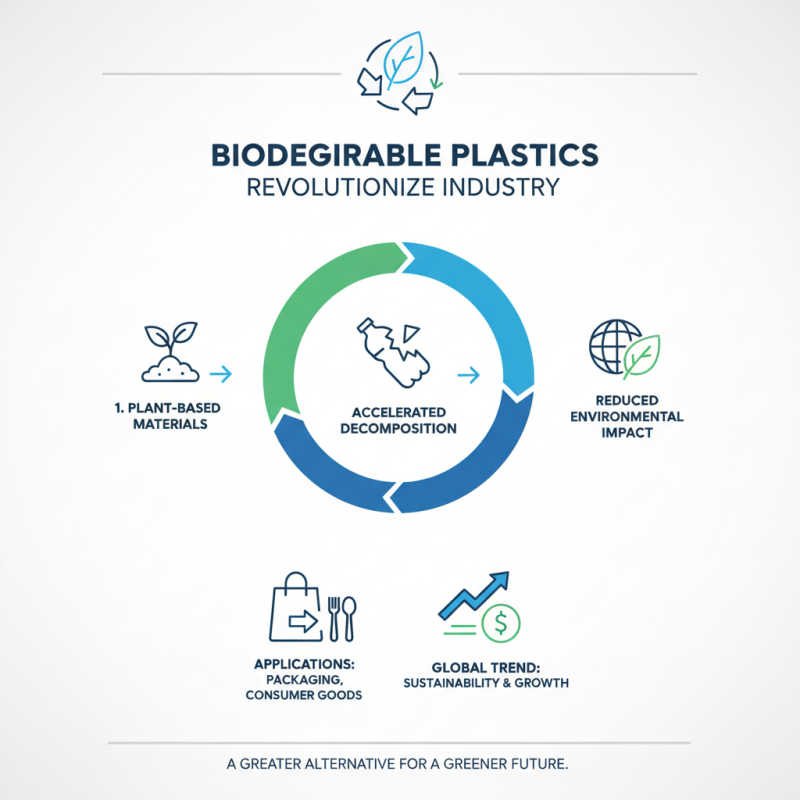

Innovations in Biodegradable Plastics and Their Market Impact

Innovations in biodegradable plastics are changing the landscape of plastic production. With rising environmental concerns, these materials offer a more sustainable alternative. They break down more quickly than traditional plastics. This trend is gaining traction in various industries, from packaging to consumer goods.

When considering biodegradable options, it’s vital to understand the material's composition. Not all biodegradable plastics are equal. Some may require specific conditions to decompose fully. This can lead to confusion among consumers. Awareness is key. Research the types of biodegradable plastics available and their environmental impact.

Tips: Always look for certifications that ensure a product's true biodegradability. Engage with suppliers to clarify how their products decompose. Consider local waste management practices. These can influence how effectively biodegradable plastics perform in your area.

This innovation is not without challenges. The high production costs can hinder widespread adoption. There are also concerns about the potential for these materials to contaminate recycling streams. Educating consumers will be crucial as the market evolves. We must remain mindful of these complexities and continue to push for more sustainable solutions.

Advancements in Recycling Technologies for Plastic Waste Management

The advancements in recycling technologies for plastic waste management are remarkable. In 2026, estimates suggest that recycling rates could reach 35%, up from 20% in 2020. Innovative techniques are emerging, such as chemical recycling, which allows for the processing of mixed plastics. This method breaks down waste into its fundamental components, making recycling more efficient.

Tips: Stay informed about local recycling programs. Every region may have different guidelines and technologies in place. Participate actively in community clean-up efforts to boost local recycling rates. Small actions lead to large impacts.

Despite these advancements, challenges remain. Not all plastics are suitable for recycling, creating a backlog of materials. According to industry reports, nearly 50 million tons of plastic waste are generated annually, with a significant portion still ending up in landfills. Alternatives and improvements are necessary to tackle this mounting issue effectively.

Tips: Reduce plastic use wherever possible. Mindful consumption can help alleviate strain on recycling systems. Consider alternatives, such as biodegradable materials, when practical.

2026 Best Innovations in Plastic Production Technologies and Trends

| Technology | Description | Trend Impact | Recycling Efficiency | Year Introduced |

|---|---|---|---|---|

| Chemical Recycling | Conversion of plastic waste into raw materials through chemical processes. | Increases recovery rates of difficult-to-recycle plastics. | High | 2024 |

| Bio-based Plastics | Plastics made from renewable biomass sources. | Aligns with sustainability goals and reduces fossil fuel dependence. | Moderate | 2023 |

| Advanced Sorting Technologies | AI and machine learning to improve the sorting of plastics for recycling. | Enhances the purity of recycled materials. | High | 2025 |

| Additive Manufacturing | 3D printing with recycled plastics as feedstock. | Promotes closed-loop systems in production. | Moderate | 2022 |

| Microbial Degradation | Using microorganisms to break down plastic waste into biodegradable substances. | Innovative solution for waste management and pollution reduction. | High | 2024 |

Trends in Automation and Smart Manufacturing in Plastics Industry

The plastics industry is witnessing a transformation through automation and smart manufacturing. Companies are integrating advanced technologies like IoT and AI. These innovations aim to enhance productivity, reduce waste, and improve quality. However, the transition is not without challenges. Many companies struggle with the adoption of these complex systems. It's crucial to evaluate the existing workforce's readiness and adapt to new skills.

Smart manufacturing in plastics also focuses on data-driven decision-making. Sensors embedded in machinery provide real-time insights. This allows for better monitoring and predictive maintenance. Yet, there are gaps in data integration across systems. Many organizations must work on standardizing processes to benefit fully. They face difficulties in managing vast amounts of data.

Moreover, the push for sustainability adds another layer of complexity. Manufacturers must comply with stringent regulations while innovating. Balancing automation and environmental responsibility is crucial. The path forward is riddled with uncertainties, requiring continuous reflection and adaptation. Engaging with employees and fostering a culture of learning can help navigate this evolving landscape.

Related Posts

-

How to Choose the Right Plastic Inc Company for Your Needs?

-

Effective Ways to Reduce Plastic Waste in Your Business Operations

-

What is Plastic Production and Its Impact on the Environment?

-

How to Choose the Right Plastic Company for Your Manufacturing Needs

-

Top Insights on Plastic Manufacturing Industry Trends and Innovations

-

10 Best Injection Molded Parts for Your Manufacturing Needs

Our Promise to You

All products and services provided by Innovative Plastic Molders, Inc. will meet or exceed our customer's perceived requirements and expectations. We will listen and respond to what our customers are telling us in a timely and forthright manner.

ISO 9001:2015 CERTIFIED

© Copyright 2009 – Innovative Plastic Molders, Inc.

Website by Central 8 Marketing

Contact IPM

10451 Dog Leg Road Ste 200

Vandalia, OH 45377

Phone: 937.898.3775

Fax: 937.535.0640

Email: sale@endtheplastic.com