BLOG

Top 10 Benefits of Injection Tooling You Need to Know About

Injection tooling is a critical component in modern manufacturing, driving efficiency and precision across various industries. According to the 2023 Plastics Industry Association report, the injection molding sector alone accounted for over $120 billion in U.S. revenue last year, highlighting its essential role in production. As the demand for customized components and quick turnaround times continues to rise, understanding the benefits of injection tooling becomes imperative for industry professionals.

Expert insights emphasize the significance of this manufacturing process. Dr. Emily Carter, a leading authority in injection molding technology, notes, "The advancements in injection tooling not only improve production efficiency but also enhance product quality, leading to substantial cost savings for manufacturers." This underscores the transformative impact of injection tooling in modern production environments, where manufacturers strive for both innovation and sustainability.

In exploring the top benefits of injection tooling, this article aims to equip professionals and stakeholders with essential knowledge to harness its full potential, ensuring they remain competitive in an ever-evolving market. The insights provided herein will be invaluable for decision-makers looking to optimize their manufacturing processes and achieve superior results.

Advantages of Injection Tooling in Mass Production Efficiency

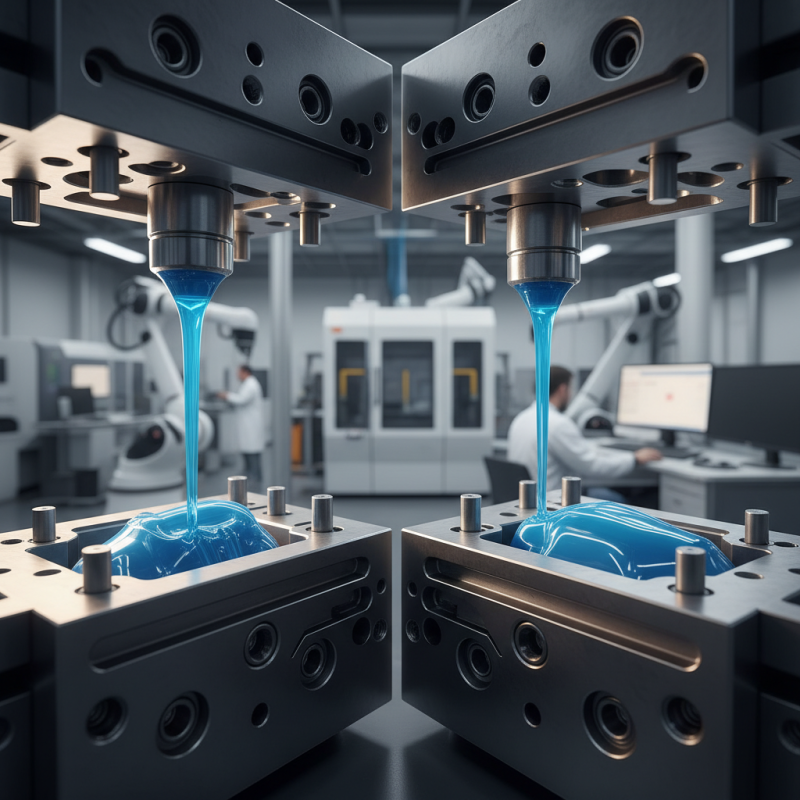

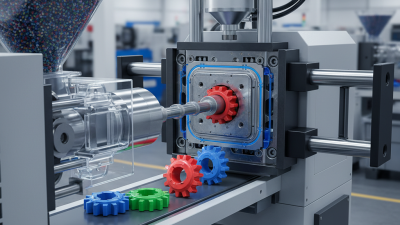

Injection tooling is a pivotal technology in the realm of mass production, offering substantial advantages in creating high-quality components efficiently. One of the primary benefits is its ability to produce large quantities of parts in a relatively short timeframe. The process involves injecting molten material into a precisely engineered mold, which solidifies to form the desired shape. This rapid production capability significantly reduces lead times, making it an ideal choice for industries that demand quick turnaround on large orders.

Moreover, injection tooling enhances consistency and precision in manufacturing. Once the mold is created, each subsequent part produced is nearly identical, ensuring uniformity that is crucial for applications where exact specifications are vital. This precision limits the need for extensive post-manufacturing processes such as machining or adjustments, ultimately saving both time and resources. Additionally, with advancements in tooling technology, manufacturers can achieve intricate designs and complex geometries that were previously challenging or impossible, further broadening the scope of applications for injection molded components.

Cost-Effectiveness: Analyzing Material Usage and Waste Reduction

Injection tooling is renowned for its cost-effectiveness, particularly when it comes to material usage and waste reduction. By utilizing precision manufacturing techniques, injection molding minimizes excess material during production, significantly lowering costs associated with raw materials. The process allows manufacturers to create complex parts in a single cycle, reducing the need for secondary operations that can generate additional waste. Moreover, the ability to recycle scrap material back into the production process not only conserves resources but also helps in maintaining a sustainable manufacturing environment.

Tips for maximizing cost-effectiveness in injection tooling include optimizing the design phase to minimize material usage. Engineers should focus on creating designs that achieve the required functionality with the least amount of material, which can be accomplished through advanced simulation software. Another tip is to consider the choice of materials judiciously; selecting materials that are not only compatible with the injection process but also offer durability can reduce overall production costs in the long run.

Additionally, maintaining the injection molding machinery in top condition can greatly impact efficiency and waste reduction. Implementing a regular maintenance schedule ensures that equipment operates at peak performance, leading to fewer defects and reduced scrap rates. Investing in employee training on best practices can further enhance production efficiency and contribute to effective waste management strategies, ultimately reflecting positively on the bottom line.

Precision and Quality: Statistical Data on Tolerance Levels Achieved

Injection tooling is a key player in manufacturing processes, particularly when it comes to achieving high levels of precision and quality. According to a report published by the International Society of Automation, modern injection molding can achieve tolerance levels as tight as ±0.001 inches, which is crucial for industries that require intricate designs and reliable product performance. This precision is mainly attributed to advancements in tooling technology, which have allowed for enhanced mold designs and the incorporation of advanced materials that withstand high pressures and temperatures.

Furthermore, statistical data reveals that approximately 90% of injection-molded parts fall within the specified tolerance levels, significantly minimizing the need for rework and reducing material waste. A study from the Society of Plastics Engineers highlights that with optimized injection tooling, manufacturers can achieve an impressive defect rate of less than 1%. This not only boosts production efficiency but also enhances customer satisfaction by ensuring that the final products meet or exceed quality expectations. The ability to consistently produce parts with minimal variation solidifies injection tooling's reputation as a leading method for precision manufacturing across various sectors.

Flexibility in Design: Case Studies Illustrating Versatile Applications

Injection tooling has revolutionized the manufacturing landscape, particularly in its ability to adapt to various design requirements. A significant advantage of this approach is its flexibility, enabling customized production without substantial lead times. Case studies illustrate a wide array of applications, from automotive components to intricate medical devices, demonstrating how businesses can save time and reduce costs while meeting specific market demands. According to a report by the American Injection Molding Association, over 70% of companies noted a marked increase in efficiency when employing advanced injection tooling techniques.

When designing for injection molding, it is essential to consider the potential for rapid prototyping and iterative testing. This flexibility allows designers to alter molds quickly based on feedback or new design requirements, significantly shortening the overall product development cycle. Tips for leveraging this flexibility include involving cross-functional teams early in the design phase to gather diverse insights, and utilizing computer simulations to optimize tool design before manufacturing begins.

Additionally, the ability to produce complex geometries with injection molding opens up new possibilities for innovation. Designers can explore intricate shapes and features that were previously deemed unmanufacturable. This aspect is crucial in sectors like consumer electronics, where aesthetics and functionality often collide. By embracing advanced software tools and simulation technologies, designers can pinpoint the best variations for functionality and minimize wastage, amplifying their creativity while maintaining efficiency.

Speed of Production: Time Metrics Compared to Other Manufacturing Methods

Injection tooling is renowned for its impressive speed of production, significantly outpacing other manufacturing methods. This efficiency is primarily due to the rapid cycle times involved in the injection molding process. Typically, parts can be produced in mere seconds, making it ideal for high-volume production runs. In comparison to techniques like machining or 3D printing, which can take considerably longer for each unit, injection molding offers a streamlined approach that minimizes downtime and maximizes output.

When considering injection tooling, it’s essential to focus on optimizing the cycle times. Here are some tips to enhance your production speed: First, ensure that your molds are designed for efficient cooling. Proper cooling pathways can significantly reduce the time it takes for the material to set. Additionally, investing in high-quality machinery can provide faster injection speeds and enhance overall precision. Finally, conduct regular maintenance checks to prevent unforeseen delays caused by equipment malfunctions.

Understanding the time metrics involved in injection tooling allows manufacturers to plan more effectively. Compared to other methods, the swift production capability of injection molding not only cuts lead times but also supports rapid prototyping and product iteration. By leveraging the benefits of injection tooling, businesses can stay ahead of the competition while meeting the demands of the market efficiently.

Speed of Production: Injection Tooling vs Other Manufacturing Methods

This chart compares the production speed of different manufacturing methods. Injection molding stands out with the highest production speed, making it an efficient choice for high-volume production.

Related Posts

-

How to Optimize the Injection Moulding Process for Better Efficiency and Quality

-

Exploring the Future of Injection Tooling Innovations and Trends

-

Understanding the Role of Plastic Injection Companies in Sustainable Manufacturing Practices

-

How Custom Injection Molded Parts Revolutionize Modern Manufacturing Techniques

-

Understanding the Plastic Injection Moulding Process for Efficient Manufacturing

-

2025 Guide: How Custom Plastic Molding Drives $35 Billion Industry Growth

Our Promise to You

All products and services provided by Innovative Plastic Molders, Inc. will meet or exceed our customer's perceived requirements and expectations. We will listen and respond to what our customers are telling us in a timely and forthright manner.

ISO 9001:2015 CERTIFIED

© Copyright 2009 – Innovative Plastic Molders, Inc.

Website by Central 8 Marketing

Contact IPM

10451 Dog Leg Road Ste 200

Vandalia, OH 45377

Phone: 937.898.3775

Fax: 937.535.0640

Email: sale@endtheplastic.com