BLOG

Top 10 Benefits of Custom Plastic Injection Molding for Your Business

In today's highly competitive manufacturing landscape, businesses are continually seeking innovative solutions to enhance efficiency and reduce costs. One such solution that has gained significant traction is custom plastic injection molding, a process that allows companies to create intricate plastic parts tailored to their specific needs. According to a report by MarketsandMarkets, the global injection molding market is projected to reach $341.5 billion by 2025, underscoring the growing importance of this technique in various industries including automotive, consumer goods, and medical equipment.

Experts in the field, such as Dr. Mark Schneider, a leading authority on plastic manufacturing, emphasize the transformative potential of custom plastic injection molding for businesses. He states, "Custom plastic injection molding not only improves product design flexibility but also significantly reduces production turnaround times, which are critical for maintaining a competitive edge." This method enables companies to optimize material usage, minimize waste, and harness advanced designs that enhance overall product performance. As we delve deeper into the top 10 benefits of custom plastic injection molding, it becomes clear why this technology is an invaluable asset for any forward-thinking enterprise looking to thrive in an evolving market.

Benefits of Tailored Design Solutions in Custom Plastic Injection Molding

Custom plastic injection molding offers significant advantages for businesses, particularly when it comes to tailored design solutions. One of the primary benefits of custom molding is the ability to create parts that meet specific design requirements, ensuring that the final product aligns perfectly with the intended function and aesthetic. This degree of customization allows businesses to differentiate their offerings in a competitive market, catering to unique customer demands and enhancing brand identity.

Moreover, tailored design solutions can lead to increased efficiency during the production process. By designing molds that optimize material use and reduce waste, companies can lower manufacturing costs while maintaining high-quality standards. Additionally, advanced engineering techniques enable faster turnaround times, allowing businesses to respond quickly to market changes. This agility is crucial in industries where time-to-market can significantly impact profitability and market relevance. Ultimately, custom plastic injection molding empowers businesses to innovate and adapt, driving growth through bespoke solutions that reflect their unique value propositions.

Cost Efficiency Achieved through Custom Plastic Injection Molding

Custom plastic injection molding is renowned for its ability to significantly enhance cost efficiency for businesses across various industries. According to a report by Grand View Research, the global plastic injection molding market was valued at approximately $237 billion in 2020 and is expected to experience a compound annual growth rate (CAGR) of 5.6% from 2021 to 2028. By adopting custom solutions, companies can optimize production processes, reducing both labor and material costs significantly.

One of the primary cost benefits of custom plastic injection molding lies in the reduction of waste material. Traditional manufacturing methods often result in excess scraps, while precision molding minimizes material loss, leading to lower raw material expenses. A study from the Journal of Cleaner Production highlighted that businesses utilizing advanced injection molding techniques could achieve up to a 30% reduction in overall material costs. Furthermore, the high production efficiency of this method enables businesses to produce large volumes in shorter time frames, ultimately decreasing the cost per unit. This efficiency not only contributes to direct savings but also supports faster time-to-market, giving companies a competitive edge.

Enhanced Product Quality through Precision Manufacturing Techniques

Custom plastic injection molding is transforming the landscape of product manufacturing, particularly by enhancing product quality through its precision manufacturing techniques. This method allows for the consistent production of high-quality components that meet exact specifications. The ability to maintain tight tolerances ensures that each item produced is uniform, which minimizes the risk of defects and significantly boosts overall product reliability.

Moreover, the precision achieved in custom plastic injection molding enables businesses to create complex designs that would be difficult or impossible to achieve with traditional methods. This capability not only facilitates innovation but also meets the evolving demands of consumers who seek unique and functional products.

Tips: When considering custom plastic injection molding, it's crucial to collaborate closely with your manufacturing partner during the design phase. Early discussions about design feasibility can save time and resources later on. Additionally, always prioritize materials that are best suited for your application; the right material can significantly enhance the performance and longevity of your product. Lastly, regular quality checks throughout the production process can help maintain high standards and ensure that every batch meets your quality requirements.

Flexibility and Scalability in Production with Custom Molding Solutions

Custom plastic injection molding offers unparalleled flexibility and scalability in production, making it an ideal choice for businesses looking to optimize their manufacturing processes. One of the primary advantages of custom molding solutions is the ability to tailor designs to meet specific needs, allowing companies to produce parts and products that closely align with their requirements. This adaptability is crucial in rapidly changing markets where customer preferences and technological advancements demand quick updates to products. With custom molds, businesses can experiment with different designs and materials without the significant cost typically associated with retooling.

In addition to flexibility, custom plastic injection molding provides excellent scalability, enabling businesses to seamlessly adjust production volumes in response to market demand. Whether a company requires small batches for testing or large-scale manufacturing, custom molding solutions can accommodate fluctuating needs without compromising quality. This scalability not only reduces lead times but also improves resource management, allowing businesses to maximize efficiency and minimize waste. As companies continue to navigate the complexities of modern production, embracing the adaptability of custom plastic injection molding can position them for long-term success and innovation.

Top 10 Benefits of Custom Plastic Injection Molding for Your Business

| Benefit | Description |

|---|---|

| Cost Efficiency | Bulk production reduces per-unit costs, maximizing profit margins. |

| Design Flexibility | Allows for intricate designs and complex geometries that meet specific needs. |

| Scalability | Easily scale production volumes up or down based on demand. |

| Product Consistency | High repeatability ensures uniform quality across all products. |

| Material Variety | Wide selection of materials, including specialized plastics for various applications. |

| Rapid Prototyping | Quickly create prototypes for testing and evaluation before full production. |

| Reduced Waste | Efficient production minimizes excess material waste, supporting sustainability. |

| Enhanced Strength | Molded parts typically exhibit better structural integrity compared to other processes. |

| Shortened Lead Times | Streamlined processes enable faster product delivery to market. |

Streamlined Production Processes and Time Savings in Manufacturing

Custom plastic injection molding stands out as a key player in streamlining production processes for businesses. By adopting this manufacturing method, companies can significantly reduce production time due to its ability to create complex shapes with high precision in one cycle. This efficiency is enhanced by the automation of the injection molding process, which minimizes human error and ensures consistency across large production runs. As a result, businesses can meet increased demand without sacrificing quality, aligning with tight production schedules.

Moreover, the time savings derived from custom plastic injection molding enable businesses to accelerate their go-to-market strategies. With faster production times and the ability to prototype quickly, organizations can refine their products based on market feedback without the lengthy delays typically associated with traditional manufacturing methods. This agility not only allows companies to respond swiftly to changing consumer needs but also fosters innovation by providing the capability to experiment with new designs and materials, ultimately driving growth and competitiveness in the marketplace.

Related Posts

-

Top 10 Tips to Choose the Right Injection Machine for Your Manufacturing Needs

-

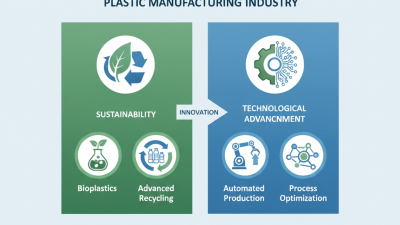

Top Insights on Plastic Manufacturing Industry Trends and Innovations

-

How to Optimize the Injection Moulding Process for Better Efficiency and Quality

-

Everything You Need to Know About Plastic Trim: Uses, Benefits, and Maintenance Tips

-

2025 Guide: How Custom Plastic Molding Drives $35 Billion Industry Growth

-

2025 How to Choose the Best Plastic Injection Molding Machine for Your Needs

Our Promise to You

All products and services provided by Innovative Plastic Molders, Inc. will meet or exceed our customer's perceived requirements and expectations. We will listen and respond to what our customers are telling us in a timely and forthright manner.

ISO 9001:2015 CERTIFIED

© Copyright 2009 – Innovative Plastic Molders, Inc.

Website by Central 8 Marketing

Contact IPM

10451 Dog Leg Road Ste 200

Vandalia, OH 45377

Phone: 937.898.3775

Fax: 937.535.0640

Email: sale@endtheplastic.com